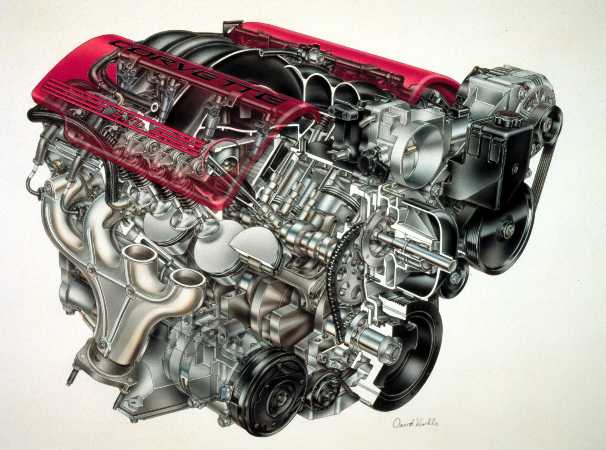

2001 Corvette LS1 vs. 2001 Corvette Z06 LS6 Engine Comparison

A listing of engine specifications between the 2001 Corvette LS1 engine and the 2001 Corvette Z06 LS6 engine.

The Corvette Action Center would like to thank Hib Halverson, Corvette Journalist, Internet Contributor of Corvette Material and Corvette Action Center Community Member for help with some of the specifications listed below.

| Click on pictures for enlarged size. | ||

|---|---|---|

|

|

|

| Component | 2001 LS1 | 2001 LS6 | ||

|---|---|---|---|---|

| Type | Overhead valve, pushrod V-8 | |||

| Block | Cast aluminum, 107.1 lbs (48.6 kg) | |||

| Block Deck Height | 9.24 in. (234.7 mm) | |||

| Stroke (in./mm) | 3.90 x 3.62 /99.0 x 92.0 | |||

| Cam Drive | Chain | |||

| Camshaft | Hollow steel | |||

| Combustion Chamber Volume | 4.1 cu. in. (67.3 cu. cm) | |||

| Connecting Rods | PF1159M steel, sintered, forged and shotpeened, 6.1-inches | |||

| Crankshaft | Cast nodular iron with undercut and rolled fillets | |||

| Cylinder Head | Aluminum, 2 valves/cylinder, 20.3 lbs (9.2 kg) | |||

| Displacement | 346 cu in, 5665 cc, 5.7 L | |||

| Exhaust Manifolds | Cast nodular iron | |||

| Firing Order | 1-8-7-2-6-5-4-3 | |||

| Fuel Injection | sequential electronic fuel injection | |||

| Fuel Requirement | Premium unleaded | |||

| Ignition | Individual-coil, DIS (distributorless ignition system) with double-platinum-tipped spark plugs | |||

| Intake Manifold | Composite, 15.9 lbs. (7.2 kg) | |||

| Lifters | Hydraulic roller type | |||

| Main Bearing Caps | Powdered metal | |||

| Rocker Arms | Investment cast steel with a roller fulcrum but a standard tip | |||

| Valve Lift (Intake/Exhaust)(in.) | 0.500/0.500 | 0.525/0.525 | ||

| Valve Lift Duration(Intake/Exhaust)(degrees) | 198/208 | 204/211 | ||

| Output | ||||

| Horsepower (hp @ rpm) | 350 @ 5,600 | 385 @ 6,000 | ||

| Torque (lb-ft @ rpm) | 375 @ 4,400(manual) 360 @ 4,000(auto.) |

385 @ 4,800 | ||

| Redline (rpm) | 6,000 | 6,500 | ||

| Fuel Cutoff | 6,200 | 6,600 | ||

| Compression Ratio | 10.1:1 | 10.5:1 | ||

| Manufacturing Origin | St. Catherines, Ontario | |||

| Total Dressed Engine Weight | Auto. - 457.6 lbs. (208 kg); Manual - 497.2 lbs (226 kg) |

497.2 lbs (226 kg) | ||

2001 Corvette Z06 LS6 Mofifications:

- Redesigned engine block includes quarter size slots cast into the webs underneath the travel area of the piston which reduces the amount of air the pistons pump resulting in higher rpm output.

- Redesigned positive crankcase ventilation system improves oil flow during high speed conditions.

- Redesigned air cleaner leading to reduced restriction and greater air intake.

- Redesigned camshaft profile which allows increased valve lift, therefore more air pulled into the combustion chamber which helps to increase power.

- New intake manifold and mass air flow sensor design allows more air intake.

- Higher rate valve springs and a new cylinder head design enhance the engine's breathing characteristics for increased rpm and performance.

- New cast iron exhaust manifolds are used in place of the stamped steel manifolds which improves the flow of exhaust gases. These manifolds connect to a new lightweight, titanium exhaust system which is the first ever to be used in a mass-produced automobile. This new exhaust system incorporates titanium exhaust pipes and mufflers that contain larger louver tubes which help to reduce back pressure and increase performance.