A Dose of Digital: Part 1 - The Basics - Page 2 of 5

|

|

© 2010 by Hib Halverson

No use without permission, All Rights Reserved

![]() Discuss this article

Discuss this article

How does it all work?

Executive summary: the computer, based on its programming and information coming in from sensors, controls engine functions with its actuators.

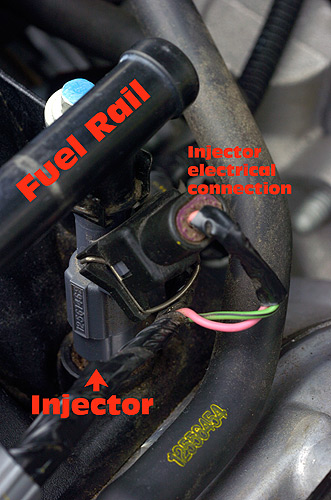

For example: the electronic control module (we'll use that term for both ECMs and PCMs) determines how much air is flowing into the engine, either by directly measuring it with a mass airflow (MAF) sensor, or deriving it mathematically by applying measured engine speed and manifold pressure to engine displacement and volumetric efficiency programming.

That data is applied to the ECM's air/fuel ratio tables and from that, the ECM "decides" how long to open the engine's electric fuel injectors, or, in the case of '80 California cars and all '81s with E4ME Quadrajet carburetors, how long to open the mixture control solenoid. That length of time, called the "pulse width" or "duty cycle", along with the size of the injector's orifices and fuel pressure, determine how much fuel is metered.

Click image for larger view

MAF sensors were used from '85-'88 and from '94-'10. They directly measure air flow. The ECM reads the frequency output an oscillator circuit in the MAF produces and that equates to air flow. Shown is the '02-'04 LS6 MAF. LT1, LT4, LS1, '01 LS6, LS2, LS3, LS7 and LS9 MAFs are similar in appearance, but have a honey-cell screen ahead of the wires.

Image: Author

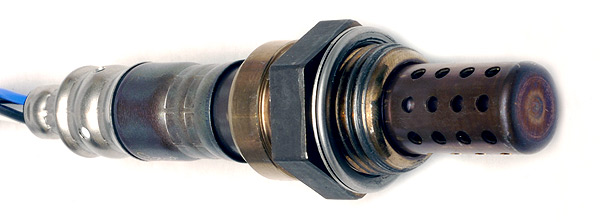

Another example? The ECM monitors residual oxygen in the exhaust, an indirect, but accurate measure of the engine's air/fuel ratio, with an oxygen sensor (O2S), or in the case of '92-up engines, two O2Ses. It uses that information to fine-tune or "trim" the injector pulse width. If the O2S reads the exhaust as a little rich; the ECM shortens pulse width, slightly decreasing fuel flow. If the exhaust is lean, the pulse width is lengthened to add a little extra fuel. This is a "feedback" loop and keeps the part-throttle, air/fuel ratio as close to stoichiometric as possible. Oh yeah-that 25-cent word? it's pronounced "stoy-key-oh-meah-trick" and means "perfect" chemical reaction with no excess reactants, ie: combustion of gasoline with only nitrogen, carbon dioxide and water in the exhaust.

Mass airflow or "MAF" sensors have been used on some Corvettes since 1985 and on all Vettes since 1994. The name is literal, ie: a MAF sensor senses the mass of the air flowing into the engine. The signal it generates and sends to the ECM directly relates to the quantity of air taken into the engine. While 85-88 L98s used a "hot wire" MAF, the current MAF sensor on Vettes is a "cold-wire" type made by Delphi.

The hot wire MAFs measured the current required to keep the hot wire at a certain temperature. The amount of current increases as air flow increases and cools the wire, thus the current flow directly relates to the mass of air flowing into the engine.

With the cold wire design, inductance of each of several sensors changes with the mass of air flowing around them. These sensors are in an oscillator circuit, the output frequency from which changes with their inductance. This oscillating signal is fed to the ECM and that always-changing output frequency is a measure the mass of air passing through the sensor and into the engine.

Click image for larger view

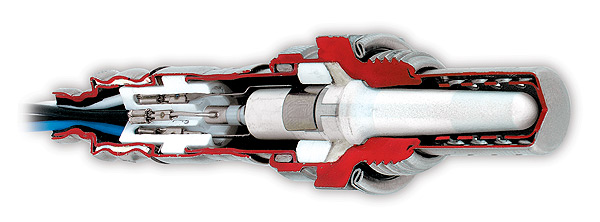

Knock sensors in Corvettes from the early-80s until 1996 looked generally like this. This unit is designed to screw into the engine block. Just because knock sensors may look alike doesn't mean they all function the same. When replacing a KS, use only the one GM specifies for your engine.

Image: Author

Spark advance is, also, electronically-controlled. The ECM uses: engine speed and TDC #1 position information from sensors located either in the distributor, in the crankcase or inside the front cover; information from the manifold absolute pressure (MAP) sensor to determine load and signals from the engine coolant temperature (ECT) and intake air temperature (IAT) sensors as to the engine's operating temperatures. It applies all that info to its programming and determines the ideal spark advance. Spark, also, uses a feedback loop.

Starting in 1982, Corvette engines are fitted with one or, starting in '92, two knock sensors (KS) which are specialized microphones which "listen" for detonation or "knock". If detonation is detected, the ECM retards timing slightly and continues to "listen". If the engine is still detonating, the computer retards spark farther. This process of listen-then-retard continues until the knock stops. After a short period, the ECM advances the spark, again, and, if the engine remains detonation free; spark continues to advance, back to the base timing appropriate for the engine speed, load and temperature.

We've used up several paragraphs just talking about fuel and spark. There are other characteristics which are computer-controlled. Learn more about all from some of the books we suggest in an accompanying sidebar.

The next painfully obvious question is: what happens when something goes wrong?

|

|