2020 - 2021 Corvette: GM TechLink: Corvette Brake Service Tips

Estimated Reading Time: 4 MinutesThe 2020 - 2021 Corvette Stingray features two brake options. RPO JL9 is the base brake system and the heavy-duty RPO J55 brake system is standard on all models with the Z51 Performance Package. (Fig. 8) The high performance brakes of the J55 system are designed for track use, with low-metallic brake pads, which help provide extreme braking performance. With its ability to perform under race track conditions, the brake system offers a trade-off in some everyday driving, such as at parking lot speeds, where there is a potential for brake squeal.

Fig. 8

Most brake squeal cases handled by the GM Technical Assistance Center (TAC) on the Corvette occur during normal, city driving. The brake squeal is intermittent and often is heard at very low speeds right before the vehicle comes to a complete stop.

Brake Squeal Diagnosis

Begin diagnosis by listening for which side, or which corner of the vehicle, the noise is actually coming from while in the service drive. It’s helpful to have an assistant standing outside of the vehicle to identify the correct location. Also ask the customer if there is a constant squeal sound, even when the brake pedal is not being applied, which may indicate that a pebble or small stone has lodged itself in between the rotor and one of the brake pads.

If a smartphone is available, any of the many available “Sound Analyzer” apps that are widely available can be downloaded to analyze the frequency of the squeal sound. By recording a short audio/video clip of the squeal sound and playing the recording into the app, it will show the frequency at which the sound is occurring. The most common frequencies of brake squeal on the Corvette are found in the 2,000–4,000 hertz range.

Applying Copper Paste

To address the potential for brake squeal, a copper paste is applied to the brake pad abutments at the factory. The paste helps to reduce the brake noise in this exact frequency range. It’s possible to wash off the paste if a customer power washes the wheels or takes the vehicle through a “no-touch” car wash. If this occurs, it will require a reapplication of the copper paste to the brake pad abutments. Refer to Bulletin #17-NA-040 for more information, including how to reapply the paste.

Brake squeal sounds above 4,000 hertz, or 4kHz, will typically not be affected by the application of the copper paste. Sounds in that frequency range are considered normal for a high performance braking system.

TIP: The battery must be disconnected to prevent the brake master cylinder from pressurizing the hydraulic system during its automated self-diagnostic tests that can possibly occur when a door is opened or the key fob is activated. Disconnecting the battery also prevents Eboost DTCs from setting when bleeding the system or seating the pistons.

When removing the front brake pads on some Z51-equipped vehicles, a piece of double-sided tape that secures the front brake pads firmly to the caliper pistons may be noticed. As shown, the blue area is the peel-and-stick double-sided tape. (Fig. 9)

Fig. 9

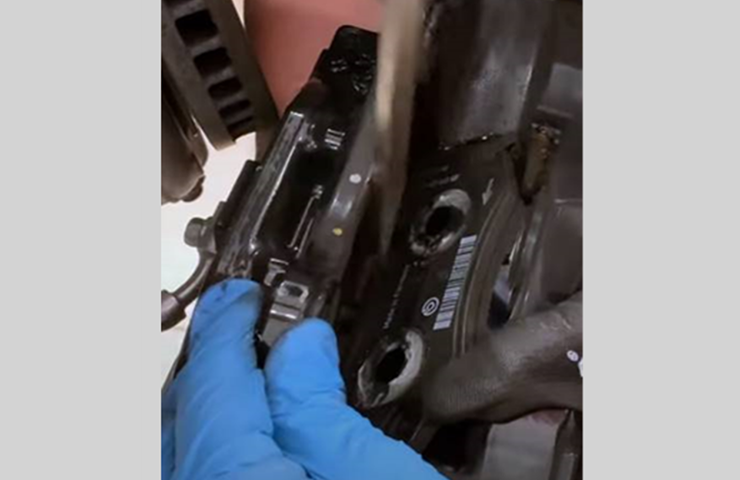

To apply the copper paste correctly, the pads must be removed from the calipers. (Fig. 10) Note that for the pads to be removed from the front calipers, the calipers must be removed from the front knuckles. Remove as much of the remaining tape residue as possible before applying the paste as directed in the bulletin.

Fig. 10

Once the copper paste has been applied to the front brake pads, reinstall them into the calipers. It’s not necessary to replace the front brake pads during this service because of the double-sided tape.

Do not chamfer the edges of the brake pads to prevent future noises from occurring. Chamfering the brake pads will not provide any noise benefit and it may result in other issues with the brake system.

TIP: It may be helpful to explain to customers that the high performance brake system will have a tendency to make some noise when used in a street setting. In low speed driving, the brakes may not have the chance to get up to “operating temperature,” so some noise is to be expected. If the vehicle continues to be driven in this type of manner, the brake squeal will almost certainly return after several days. This does not mean that there is a concern with the brakes on the vehicle.

Track Events and Brake Fluid

Both the RPO JL9 and RPO J55 brake systems use DOT 4 brake fluid. Only the RPO J55 system is designed for track use. Prior to driving at a track event, the DOT 4 fluid must be flushed out and replaced with a higher boiling temperature brake fluid. Refer to the Owner’s Manual for more information on fluid specifications. After the track event, the brake fluid should be changed back to DOT 4 fluid for street driving.

The J55 system calipers have brake bleeders on the top and bottom of the calipers. The bottom bleeder is to help with draining the brake fluid from the calipers, which is helpful when flushing the brake system after a track event. Pressure bleeding and manual bleeding are the only recommended procedures for flushing and bleeding the brake fluid. Never use vacuum bleeding on Corvette brake system.

– Thanks to Jeff Strausser