2020 Corvette: GM TechLink: 2020 Corvette Stingray Powertrain

Estimated Reading Time: 8 Minutes2020 Corvette Stingray Powertrain

GM TechLink

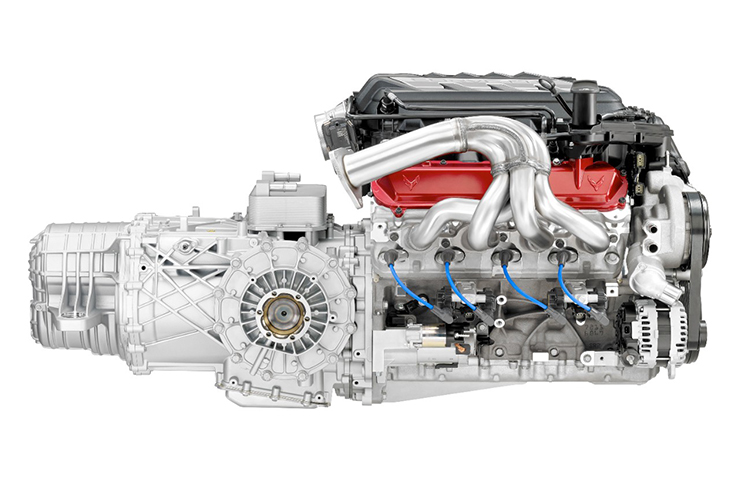

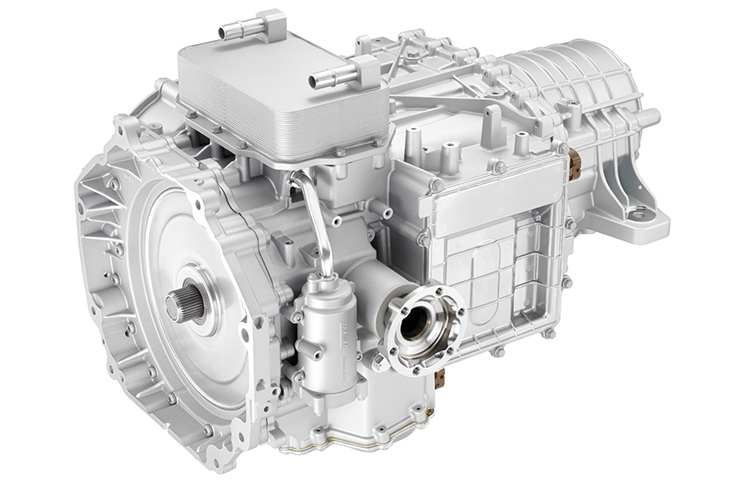

The all-new 2020 Corvette Stingray delivers exceptional performance through a combination of rear weight bias, aerodynamics, chassis tuning and its new mid-engine small block V8 and 8-speed dual clutch transmission (DCT). (Fig. 15)

Fig. 15

When equipped with the available Z51 Performance Package, the powerful V8 engine and quick shifting DCT (Fig. 16) help propel the Corvette Stingray to 60 mph (97 km/h) in 2.9 seconds and through the quarter mile (0.4 km) in 11.2 seconds at 121 mph (195 km/h).

Fig. 16

6.2L V8 Engine

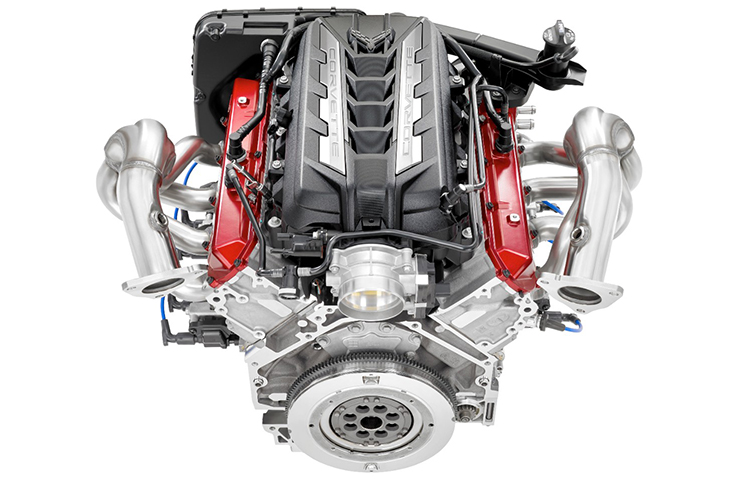

The new next-generation 6.2L V8 Overhead Valve (OHV) engine (RPO LT2) produces 495 horsepower and 470 lb.-ft. of torque when equipped with the performance exhaust. The engine features a dry sump oiling system, camshaft position actuator system (or variable valve timing) and Active Fuel Management™. The cast aluminum engine block is a cam-in-block deep skirt 90° V-configuration. (Fig. 17)

Fig. 17

Fuel System

The fuel system (Fig. 18) consists of eight separate direct injection fuel injectors, two high pressure fuel rails, a high pressure cross-over fuel pipe (connects the two fuel rails), a high pressure fuel feed pipe (connects the cross-over pipe to the high pressure fuel pump), a high pressure fuel pump and a low pressure fuel feed pipe.

The fuel injectors are each seated into their individual bores in the cylinder heads with two combustion seals to provide sealing. The Engine Control Module (ECM) supplies 65 volts to open each injector and then uses 12 volts to hold the injector open.

Fig. 18

The high pressure fuel pump, located at the rear of the engine, is driven by a three-lobe cam on the camshaft. The high pressure fuel pump supplies the necessary high fuel pressure for direct injection and regulates the fuel pressure with an actuator. A relief valve prevents excessive pressure if a failure condition is present.

Active Fuel Management™

The 6.2L V8 engine features an updated Active Fuel Management system. On previous model years, the components included the ECM, the valve lifter oil manifold assembly, and the Active Fuel Management lifters.

The new system eliminates the need for the valve lifter oil manifold assembly. Instead, four ECM-controlled valve lifter oil solenoid valves, located in the engine valley, supply oil flow to the lifters when energized by the ECM. The Active Fuel Management cylinders are 2, 3, 5, and 8.

The valve lifter oil solenoid valves are electro-hydraulic actuator devices and mount to the top of the engine valley, below the intake manifold assembly. When the ECM energizes the solenoid coil windings, the solenoid valves open, redirecting engine oil into eight separate vertical passages in the engine lifter valley and to the lifters.

Engine Lubrication and Cooling

Engine lubrication pressure is supplied by a two-stage oil pump assembly that is mounted to the front of the engine block and is driven directly off the crankshaft sprocket. The oil pump assembly consists of a primary vane-type variable displacement pump and a secondary set of gerotor-style pumps. Incorporated within the oil tank assembly are the oil level indicator, oil fill cap, positive crankcase ventilation centrifugal air/oil separator, and oil pick up screen.

Piston oil nozzles provide oil to the bottom side of each piston for cooling purposes. The piston oil nozzles have an internal check ball that remains in the normally closed position by the spring until the system oil pressure exceeds 300 kPa (43.5 PSI).

The structural cast aluminum dry-sump oil pan incorporates drain plugs, an oil pickup screen, and internal oil passages. An external oil cooler assembly mounts directly to the underside of the oil pan.

TIP: Due to the three oil pumps, the engine oil level should be checked with the engine running at operating temperature. The engine requires dexos2 0W-40 synthetic oil and has an oil capacity of 7.5 quarts (7 liters).

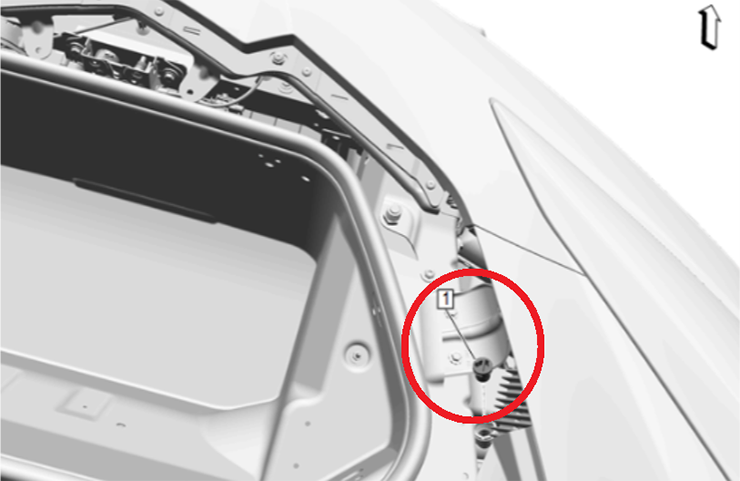

The engine cooling system of the 6.2L V8 engine requires a special bleed procedure during coolant fill. There are three bleed caps in the front of the vehicle to assist with bleeding air out of the system. One for the heater core and one for each of the front radiators. (Fig. 19)

Fig. 19

Active Exhaust System

The exhaust tailpipe flow control system changes the exhaust sound for a more aggressive sound. The system uses two tailpipe exhaust valves installed in the low restriction exhaust path of the dual outlet muffler, near the exhaust tip on each side of the vehicle. When a tailpipe exhaust valve is open, the low restriction exhaust path is opened to the atmosphere and the exhaust sound becomes more aggressive.

To provide a more aggressive exhaust note during vehicle starting, the exhaust tailpipe valves are open during an engine crank event during specific modes of operation, if equipped with the Z51 option. Once the engine is running, accelerator pedal position, transmission gear, and engine speed are used to determine the commanded state (open or closed) of the exhaust tailpipe valves.

If the vehicle is driven frequently on a track, the exhaust tips may turn blue due to high exhaust temperatures. (Fig. 20) The heat changes the color of the stainless steel and the bluing cannot be removed. This is a normal condition and mufflers should not be replaced under warranty.

Fig. 20

8-Speed Dual Clutch Transmission

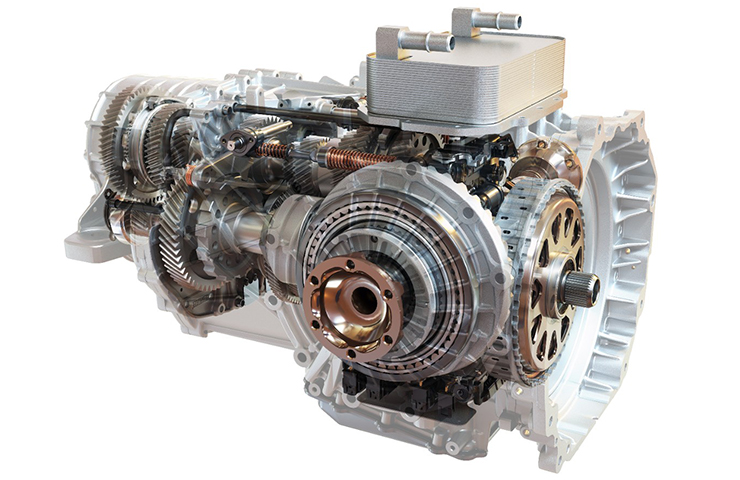

The new Tremec DCT TR-9080 8-speed transmission was designed exclusively for the 2020 Corvette Stingray and incorporates a wet dual clutch assembly, gear train assembly, and limited slip rear differential. (Fig 21)

Fig. 21

The DCT is mated to a new Electronic Transmission Range Selector (ETRS) that incorporates two pull toggles for Reverse and Drive and push buttons for Park, Neutral and Low/Manual. (Fig 22)

Fig. 22

The TR-9080 8-speed DCT features concentric clutches that are normally open with spring force. Closing action occurs from hydraulic pressure acting against rotating pistons. When the hydraulic pressure increases, the piston will apply and hold the desired clutch plates, which provide input to one of the two input shafts. The main control solenoid valve body, located in the bottom pan, controls and maintains clutch pressure.

The transmission control module controls all functions of the gearbox, including the hydraulic power system, the two clutches, the eight forward gears and reverse, and the park lock system.

Driver Modes

Driver Mode Control adds a sportier feel, provides a more comfortable ride, or assists in different weather and road conditions. The system simultaneously changes the software settings of various sub-systems to optimize driving performance. Depending on the option package, available features, and the mode selected, the exhaust, suspension, steering, brakes, and powertrain settings may change to achieve the desired mode characteristics.

Weather, Tour, Sport, and Track (Fig. 23) modes have preset vehicle settings for use in different driving conditions. My Mode and Z-Mode can be customized by the driver through the Settings menu on the infotainment screen. To activate My Mode, Weather, Tour, Sport, and Track Mode, turn the driver mode control knob on the center console to make a mode selection. To activate Z-Mode, press the Z-Mode button on the steering wheel. To deactivate, select a different mode or press the Z-Mode button again. When Z-Mode is de-activated through the Z-Mode button, Driver Mode Control is always set back to Tour Mode.

Fig 23

While in Sport, Track, My Mode or Z Mode, the transaxle may downshift while the engine RPMS stay higher, just as the C7 would in "Performance Shift Active" mode; however, the 2020 Stingray will not display the "Performance Shift Active" message in the DIC.

An external transmission cooler (Fig. 24) mounts on top of the transmission to lower the fluid temperature. There is not a required fluid flush procedure and the transmission should not be flushed.

Fig. 24

TIP: The DCT requires a special transmission fluid to maintain performance and durability standards. ACDelco DCT FFL-4 automatic transmission fluid is recommended. Do not use any other type of fluid. Total capacity is 11.62 quarts.

There also is an external oil filter located on the left side of the transmission. The transmission requires a filter change at 7,500 miles. Additional filter and fluid changes are based on the customer’s driving or track driving habits. There is a transmission oil life monitoring system to help determine the oil change intervals.

If the vehicle is being driven at a track event, two additional quarts of fluid are required. Once the extra fluid has been added, it does not need to be removed until the next required transmission oil/filter service. Use the fill plug at the top of the transmission to add the additional oil.

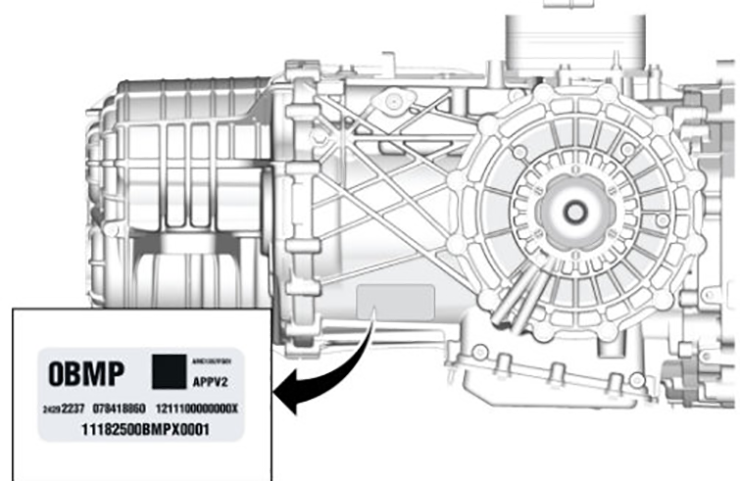

Transmission Identification

The transmission identification label is located on the right side of the transmission. (Fig. 25) It includes the part number, build information, and the Transmission Unique Number needed for programming.

Fig. 25

Manually Shifting to Neutral

With the ETRS system, the transmission parking pawl cannot be disengaged unless the engine is running. If there is a loss of vehicle battery power, the DT-52388 manual park release tool can be used to shift the transmission to Neutral and move the vehicle. Due to spring pressure, the tool must be applied to the release lever and held in the release position while moving the vehicle. The manual park release is located on the right side of the transmission and can be accessed through the trunk.

For additional information on the all-new 2020 Corvette, refer to Bulletin #20-NA-061.

– Thanks to Jeff Strausser and Matt Bunting