GM TechLink

April 30, 2024

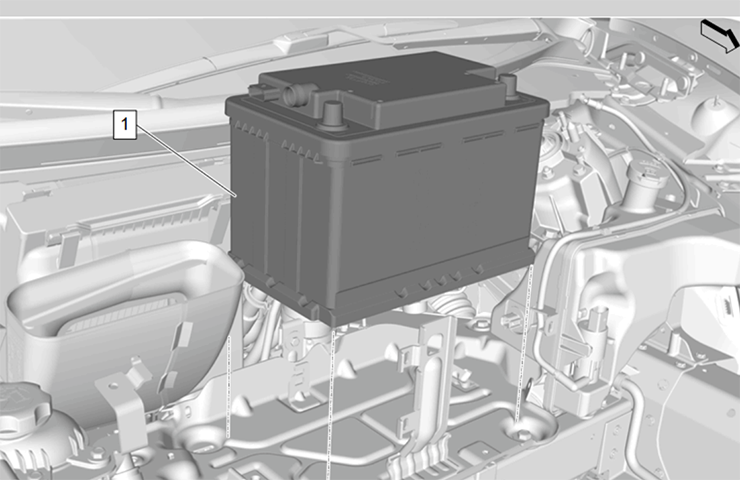

The 2024 Corvette E-Ray uses two lithium-ion batteries — one for high-voltage functions with the front electric axle and one for low-voltage operations that replaces the traditional lead-acid 12V battery. (Fig. 8)

Fig. 8

While other Corvette models have 12V flooded lead-acid batteries, the 12V lithium-ion battery in the E-Ray, also known as the 12V LiB, enables the 6.2L V8 (RPO LT2) to perform a flying start when exiting Stealth mode while driving.

The 12V lithium-ion battery is charged by the K1 14V Power Module while the vehicle is operating in the EV modes (Stealth and Shuttle modes). Once the vehicle exits an EV mode and the engine is powering the vehicle, the generator takes over 12V LiB charging.

Battery Contactors

The 12V LiB has an internal set of contactors that will open if voltage, current or temperature reach a critical state. The voltage curve is not the same as a lead-acid (PbA) 12V battery.

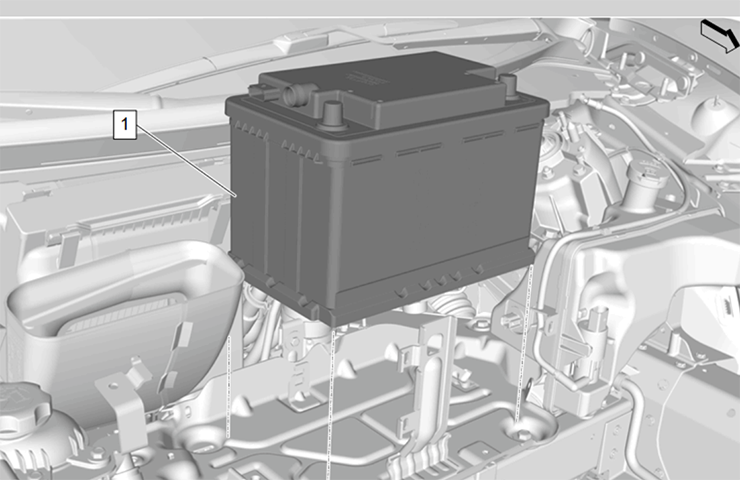

Contactor self-tests run every time the vehicle is powered down and, once the self-tests begin, are completed within 5 seconds. It may be possible to hear the contactors opening and closing. The battery communicates via CAN to the K9 Body Control Module (BCM) to provide status and DTCs. 12V battery voltage is displayed on the instrument cluster. (Fig. 9) GDS2 can be used to read scan tool information directly from the 12V LiB under the K244 Battery Management Control Module.

Fig. 9

Over Voltage - In an over-voltage condition, the relay will open in any cell that exceeds 4.0 volts, which can be expected when the battery is charged above 15 volts. The relay will close once voltage is below 15 volts.

Under Voltage - In an under-voltage condition, the relay will open if any cell drops below 2.5 volts, which may occur when the battery is discharged below 11 volts. The relay can be closed under normal conditions by charging the battery using the EL-52800 E-XTEQ Diagnostic Charge Battery Station (DCBS) or an approved charger in power supply mode.

Severe Discharge - If the battery is severely discharged — any cell drops to 1.5 volts — it will set a critical low voltage and end of life fault and the relay will not close again.

Over Current - If there is an over-current condition, such as an external short circuit, the relay will open if current exceeds 2,000 amps. The relay can be closed under normal conditions by charging the battery using an approved charger in power supply mode.

Over Temperature - The relay will open if there is an over-temperature condition where the internal temperature exceeds 185°F (85°C). The relay will close once the temperature drops below 176°F (80°C).

The lithium-ion battery will not decay like a lead-acid battery. The battery health will fall off sharply; it will never provide a slow crank. The contactors inside the battery provide protection to the battery and, if the battery fails, it may be due to the contactors not allowing power to the posts, resulting in the battery to appear to be completely dead.

The 12V LiB also has an internal control module (K244 Battery Management Control Module), which can be programmed with SPS and has data available to view in GDS2. The K244 Battery Management Control Module should not be confused with the K16 Battery Energy Control Module, which is strictly for the high-voltage battery.

SPS Programming

Stable battery voltage is critical during programming. Any fluctuation, spiking, over voltage or loss of voltage will interrupt programming. Install an approved battery maintainer or power supply that provides a steady and stable voltage to support the 12V system during SPS programming events.

The following tools are approved to provide a steady power supply while performing programming on the E-Ray. Older tools or nonapproved tools, which may not keep current flow at a proper level during programming, should NOT be used.

Battery Testing and Charging

Currently, GM does not offer an external testing method for the 12V lithium-ion battery. Do not use the EL-52800 E-XTEQ Diagnostic Charge Battery Station (DCBS) or EL-50313 Midtronics GR8 Battery Tester/Charger to perform a load test. However, these tools may be used to charge the 12V LiB. Be sure to use the proper settings on both tools to charge the 12V LiB.

Use the scan tool — Battery Management Control Module - Battery State of Charge to determine the battery's state of charge.

TIP: The 12 V LiB may be damaged if charged to more than 14.5 volts.

When using the DCBS, select "Charging," "manual battery selection", and then "Lithium" when setting up the charger. If the contactors are open, the tool will automatically detect no power and ask for confirmation. Once confirmed, the DCBS will energize the battery to close the contactors.

Refer to Bulletin #23-NA-055 for additional information and FAQs regarding using the DCBS.

When using the GR8, select "Charging," "PDI", and "In Vehicle" when setting up the charger. If the contactors are open, select "power supply mode," set the max voltage to 14.5V and allow the battery to charge for several minutes before going to a normal charge mode.

Battery Replacement

If the 12V lithium-ion battery requires replacement, the vehicle will set DTCs in accordance with emissions regulations. The DTCs should be recorded on the warranty claim.

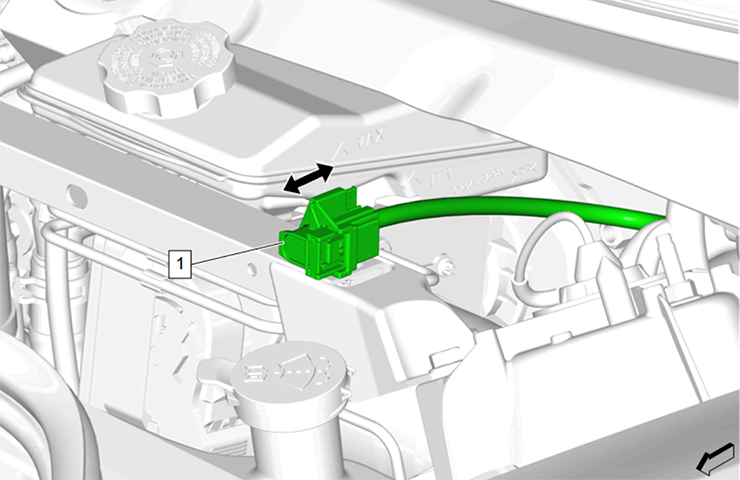

TIP: Since the 12V LiB is connected to the high-voltage system, the High-Voltage Service Lockout (HVSL) must be engaged before disconnecting the battery negative cable when replacing the battery. (Fig. 10) Engage the HSVL by lifting the red Connector Position Assurance tab and then, while depressing the connector tab, pull apart the connector halves until the indicator tab wording changes ON to OFF. Place a tie strap or a high-voltage disable padlock through the exposed HVSL hole to prevent improper re-engagement.

Fig. 10

The 12V LiB should be ordered as a regular service part through EPIC, but there will be a unique return process to be announced soon. Do not send a faulty 12V LiB to your local 12-volt battery recycler, as it is considered hazardous material and must not be mixed with other 12V batteries.

The 12V lithium-ion battery will have two new unique labor codes for warranty. If the traditional labor code for 12V batteries is submitted, the claim will be rejected. The new codes, as of April 1, 2024, are 4041430 – Battery Module Replacement and 404143E – Battery Module Replacement – Emissions. These codes do not require a printed test slip since an external test is not possible.

The appropriate Service Information diagnostics should be followed if an emissions-related fault is the cause of a battery failure. When the 12V LiB reaches its end of life, it will be indicated by the end-of-life parameter in GDS2 as set by the K244 Battery Management Control Module. The Driver Information Center message “Service Charging System Vehicle May Stall” will be displayed in the vehicle without any DTCs set.

Do not replace a 12V LiB with a lead-acid battery in a customer-pay scenario, as a number of vehicle conditions may occur with the missing control module.

– Thanks to Lane Rezek

Article ID: 1525

Created: July 16, 2024

Last Updated: August 13, 2024

Online URL: https://www.corvetteactioncenter.com/tech/knowledgebase/article/2024-corvette-e-ray-corvette-e-ray-12-volt-lithium-ion-battery-1525.html