A class action lawsuit filed in the U.S. District Court for the Central District of California – Nardizzi, et al., v. General Motors LLC regarding cracked wheels on C7 Corvettes was dismissed after the plaintiff failed to convince a federal judge the wheels were defective from the time he purchased his Corvette.

The plaintiff bought a brand new 2018 Corvette from a dealer and brought it to a third-party wheel finisher to apparently have the wheels powder-coated.

Upon inspecting the wheels prior to powder-coating, the wheel finisher recorded a video showing that the Corvette’s wheels were bent.

The plaintiff reported the issue to the selling dealer and fought the dealer and GM to cover the $7,500 replacement cost under the vehicle’s manufacturing warranty. The dealer told the plaintiff that his wheels were bent due to his driving and that repairs / replacement would not be covered under warranty. GM agreed to cover $1,200 of the $7,500 cost.

The plaintiff reported the issue to the selling dealer and fought the dealer and GM to cover the $7,500 replacement cost under the vehicle’s manufacturing warranty. The dealer told the plaintiff that his wheels were bent due to his driving and that repairs / replacement would not be covered under warranty. GM agreed to cover $1,200 of the $7,500 cost.

According to the plaintiff, GM sold and leased cars “with wheels that were defective, requiring repair or replacement within the warranty period, and refusing to honor the express warranty by repairing or replacing, free of charge, the wheels.”

The vehicle warranty applies to“any vehicle defect, not slight noise, vibrations, or other normal characteristics of the vehicle due to materials or workmanship during the warranty period.” However, GM defended the phrase “due to materials or workmanship” which clarifies which defects are covered. The judge sided with GM stating that while the warranty applies to any defect due to materials or workmanship during the warranty period, defects involving “slight noise, vibrations, or other normal characteristics of the vehicle” are not covered.

The judge continued that the warranty requires that the owner take the vehicle “to a Chevrolet dealer facility within the warranty period and request[ed] the needed repairs.” Instead, the owner took the Corvette to a third-party repair shop to have the wheels repaired and then tried to get GM to pay for the cost.

The judge also dismissed remaining claims by the plaintiff alleging that GM had prior knowledge of the Corvette wheel defects but continued to sell the vehicles anyhow.

“To successfully allege a manufacturer was aware of a defect, a plaintiff is typically required to allege how the defendant obtained knowledge of a specific defect prior to the plaintiff’s purchase of the defective product.” – Judge Carney

Judge Carney found that 30 of those claims presented by the plaintiff were filed after the plaintiff purchased his Corvette with 11 claims filed beforehand. Of those 11 claims, several of them suggest that the wheels were bent or cracked due to owner driving characteristics.

Similar Case in Michigan

Early in September, a consolidated class action lawsuit was filed in the U.S. District Court for the Eastern District of Michigan against GM for defective wheels used on the 2015 to 2019 Corvette Z06 and 2017 to 2019 Corvette Grand Sport.

This case is similar to the case above in California and was filed by Capstone Law – the same group of attorneys that represented the plaintiff in California.

One of the plaintiffs in the Michigan case, Vanessa Bishop Diggs, spent years saving up for her dream car – a 2019 Corvette Z06.

Vanessa Bishop Diggs, 66, stands with her 2019 Chevrolet Corvette Z06 on Aug. 15, 2020.

After one year of ownership and 15,000 miles, her Z06 started to experience wheel vibration and shaking. Diggs discovered that she had four bent wheels.

Like the plaintiff in California, she tried to get the cost of replacement covered under warranty, but GM argued that the wheels were bent due to her driving and they would not cover the $3,000 cost of replacement.

Diggs is one of 18 plaintiffs in this case that accuses GM of using inferior materials and faulty manufacturing processes in their products.

Corvette Wheels Cast or Forged?

In recent years, there’s been a debate about whether or not GM uses cast or forged aluminum wheels on its higher performance Corvettes such as the Z51, Grand Sport and Z06 models.

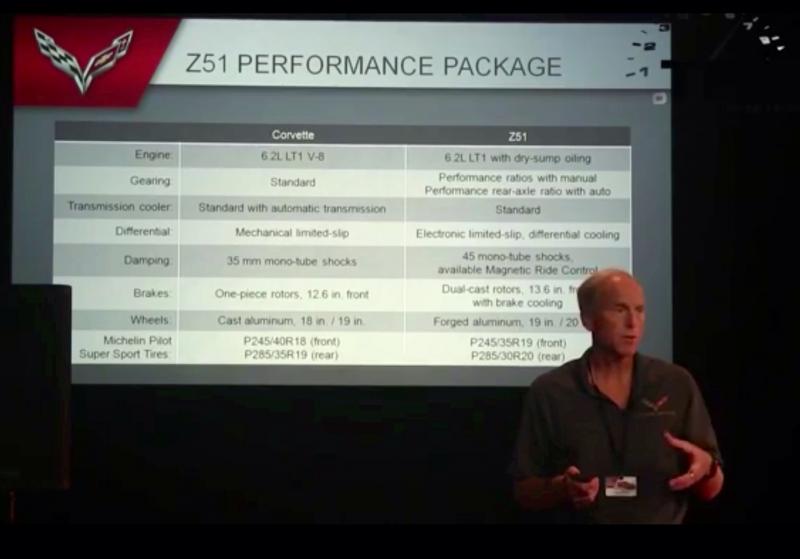

While many claim that all Corvette wheels are made from cast aluminum, Corvette Chief Engineer, Tadge Juechter confirmed during a presentation at the start of C7 Corvette production that the Z51 Corvette would use forged aluminum wheels.

Corvette Chief Engineer giving a presentation showing the differences between the standard C7 Corvette Stingray and Z51 models.

According to our research though, all C7 Grand Sport and Z06 Corvettes use cast aluminum wheels – not forged.

While OEM cast aluminum wheels are usually lighter and cheaper than aftermarket wheels, they don’t come without drawbacks.

Cast vs Forged Aluminum Wheels

So what are the differences between cast and forged wheels?

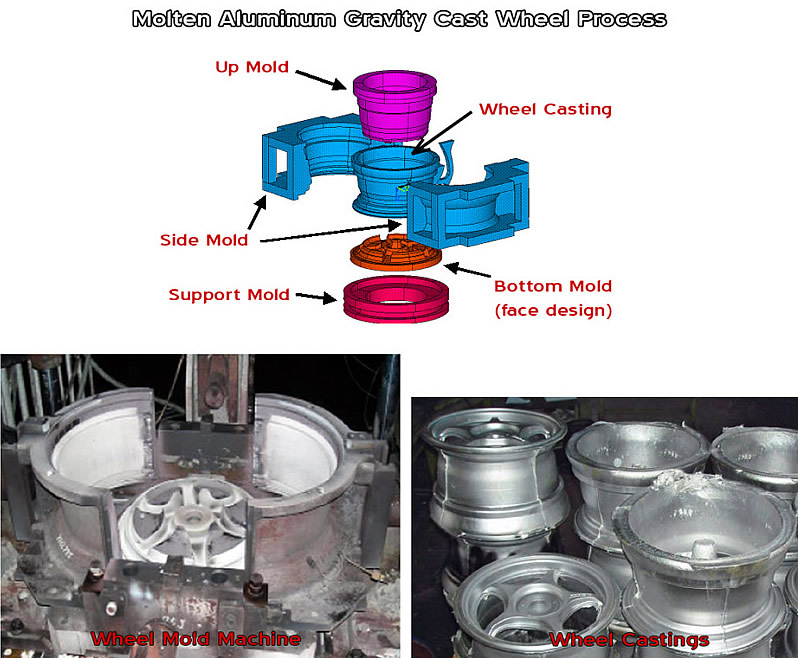

A cast wheel is made by pouring aluminum into a wheel mold where it sits until it cools. Once it cools, it’s then machined and drilled into its final form. However, one major flaw with this process is porosity.

Porosity occurs during the cooling process as small, microscopic spacing develops within the aluminum construct. Think of it as tiny air bubbles forming. This porosity can then become areas within the wheel structure which can potentially weaken and fail when exposed to stressful conditions during driving.

One way to try and overcome porosity is to use more aluminum, however that just makes the weight of the wheels heavier and more costly.

One way to try and overcome porosity is to use more aluminum, however that just makes the weight of the wheels heavier and more costly.

In order to keep cost and weight down, OEM wheel manufacturers try and keep the wheel structure within an acceptable range of tolerance. Unfortunately, this range may not always be acceptable in certain driving conditions.

While cast wheels aren’t inherently awful, a properly built cast wheel is typically suitable for street and light track use. Heavy track use is where you’ll see most low quality cast wheels fail. The catch-22 here is that a higher quality cast wheel will endure heavy track use, but it’s a heavier wheel which contributes to greater un-sprung weight and thus not ideal for this type of use where speed and timing are a factor.

Forged Wheel Composition and Manufacturing

While forged wheels are much stronger, they’re also more costly.

The two main methods for manufacturing forged wheels are machine forging and mold-form forging.

Machine Forging

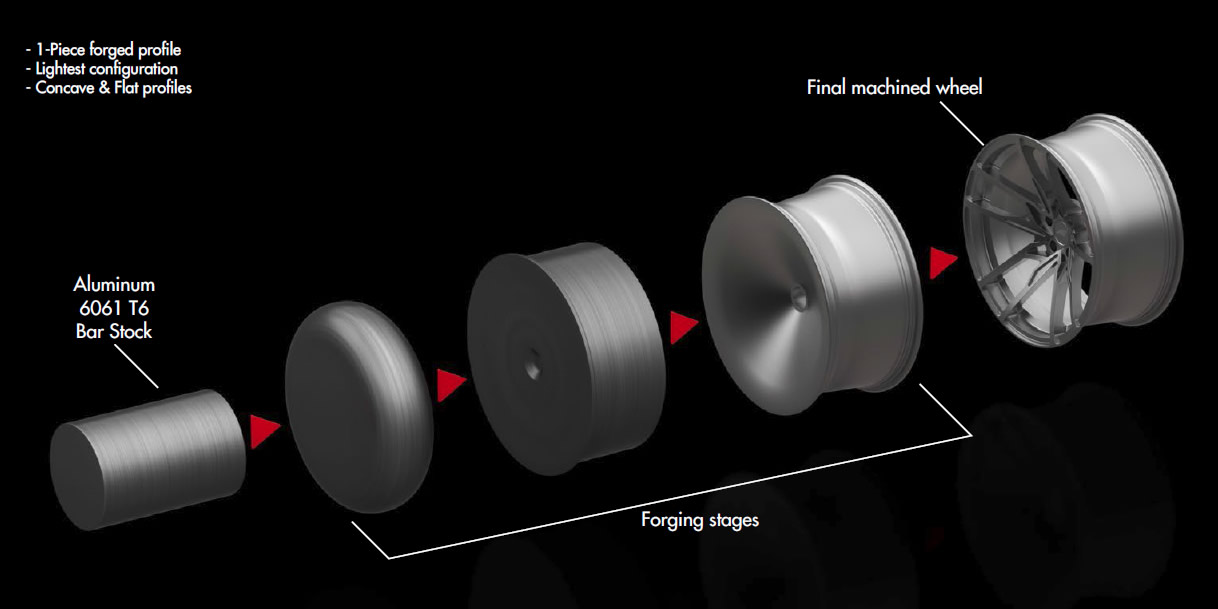

Machine forging uses a single chunk of billet aluminum and subjects it to high temperature and pressure conditions much like the process of manufacturing the C7 Corvette’s hydroformed frame rails which utilize water under high pressure to force the aluminum frame rails into the desired shape.

Subjecting the aluminum billet to these conditions actually compresses the structure thus making it much stronger than the original billet. The forged aluminum is then machine cut into the desired wheel structure.

Mold-Form Forging

Some companies that specialize in high performance wheels use a process called mold-form forging.

This process differs from the machine forging process as the shape of the wheel is actually created during the forging process instead of after. By shaping the wheel during the forging process, the aluminum particles, or “grain” actually flow with the shape of the wheel thus resulting in even greater strength than the machine forged wheels.

Once the wheels are shaped into their rough form, an enormous machine applies nearly 10,000 tons of pressure to the inner and outer parts of the wheel to create the final shape.

As you can imagine, the cost for a set of mold-form forged wheels can reach the stratosphere depending upon size.

Do Corvette Owners Have a Legitimate Case?

Given all the reports I’ve read over the last few years in forums and social media about Corvette wheels cracking, it’s quite obvious that something is amiss here.

While GM argues that the reported cases of wheel failure are due to the owners’ driving habits, potholes, etc., a couple thoughts come to mind about that:

While GM argues that the reported cases of wheel failure are due to the owners’ driving habits, potholes, etc., a couple thoughts come to mind about that:

- A vast majority of owners tend to baby their Corvettes – hell most of them go into fits of Tourette’s Syndrome and seizures if a single drop of water falls out of the sky and on to their Corvettes. Based upon my observations of members within my own Corvette club, they’ll drive 5+ miles out of their way just to avoid a pot hole.

- A fair percentage of owners drive their Corvettes as the engineers intended. Daily driving back and forth to work as well as light track use on weekends is not uncommon.

While I understand the Corvette Team’s desire to keep cost down and weight out of the car, some components of a world-class automobile like a Corvette, should not be skimped on. Wheels are one of them.

As of this writing, there have been no safety recalls issued by GM for 2015 – 2019 Corvette wheels.

So what should C7 Corvette owners do in the meantime?

Chevrolet dealers do offer a 5-year unlimited Tire and Wheel package at an average cost of $1,200 which is transferable to the next owner if you sell your Corvette.

While it’s $1,200 more out of your pocket above and beyond what you already paid for your Corvette, given the number of reported cases of wheels cracking on these cars, it’s a small price to pay for insurance, especially if you could be facing a $3,000+ bill to replace your bent or cracked wheels.

Sources: Detroit Free Press

Chime in with your thoughts in the forums!