Reports have been published lately that some customers who ordered a 2023 Corvette Z06, are still waiting to take delivery of their car. Some 2023 Z06s that were built almost two months ago, have been held up at a lot outside of the Bowling Green Corvette Assembly Plant waiting to be completed.

While GM has merely stated that the holdup is due to supply chain issues, we decided to do a little digging and see what we could find out. As a result, we recently had an interesting discussion with one of our sources who was able to potentially shed some light on the issue.

About a year after C8 Corvette production began, the tier one supplier of exposed carbon fiber parts, went belly-up and shut the doors. This left GM scrambling to find another supplier. It took that supplier a while to ramp up production, but demand for exposed carbon fiber parts remained steady and high from customers.

Carbon Fiber Supplier Issues Once Again?

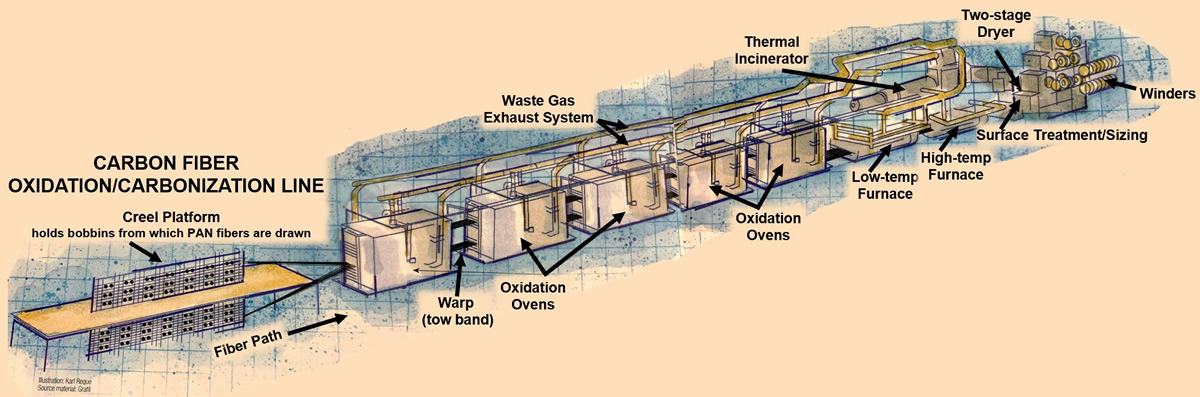

According to our source, the exposed carbon fiber supplier has not been able to keep up with production citing delays due to the baking and curing time required for the carbon fiber weave and resin to set properly. GM has been fighting with the supplier to meet demand, and the supplier has been arguing back, that they’re unable to.

Along with the inability to meet demand, the supplier has apparently increased their manufacturing costs for the exposed carbon fiber products on GM, but GM doesn’t want to pass the increased cost on to the consumer.

Ironic, given this morning’s news that the starting price of the 2024 Corvette just went up, effective yesterday.

As a result of all the fighting and bickering between GM and the supplier, supposedly attorneys have now been involved on both sides.

How true any of this is – we can’t say for sure. Obviously, neither side is speaking about it.

However, we reached out to a retire materials engineer who used to work for Textron Corporation. He was responsible for helping to develop the heat shield used on NASA’s Space Shuttle as well as well as some of the carbon fiber materials used in NASA’s rockets and Land Rover missions.

When we told him the story about the supplier unable to keep up with demand, his response was skeptical.

Basically, he said that regardless of the baking and curing times involved with carbon fiber manufacturing, once the ovens and equipment is in place for a proper assembly line, the baking and curing times become insignificant.

His take was that it seemed more plausible that there were other issues most likely involved rather than manufacturing unable to keep up with demand.

Again, how true any of this is, we cannot say for sure. But take it for what it’s worth.

We’ll update this story if more information becomes available to us.