Anyone who is calibrating (some call this “tuning” or “programming”) the ECM in their Corvette is likely doing it in the interests of improving performance and driveability along with ensuring the engine gets good fuel economy. When you’re calibrating for improved performance, you’re often setting air/fuel ratios closer to “lean limits” and, if so, whether or not all your injectors are all flowing the same amount of fuel becomes critical.

This reviewer has been using RC Fuel Injection in Torrance, California for injector flow testing, cleaning and consultation for 25 years. The folks at RC have been doing fuel injector, flow testing, cleaning and modification for about 30 years. Founded in 1969 by the late Russ Collins, RC Fuel Injection began as a maker of competition parts and as an engine builder of Honda and Suzuki motorcycle engines for drag racing.

In mid-’80s, observing the popularity of sport compact cars in drag racing and road racing, Russ Collins used his skills gained in building four-cylinder motorcycle racing engines and began to build race engines for the developing sport compact car racing movement. Most of these small four-cylinder engines were electronic port fuel injected and Collins soon found that their fuel injectors could be a big restriction. When he started researching injectors, he found that sources of information at Toyota, American Honda, Nissan and other Japanese car makers couldn’t (or wouldn’t, as the case may have been) furnish information on injector flow capacity.

Russ Collins needed to be able to flow test injectors and soon found himself designing equipment necessary to do that. By the end of the ’80s., Collins was the go-to guy for racing electronic fuel injectors. Not only was he flow testing and modifying some injectors but he also began selling a line of high-performance injectors, many of which were the superior rotating disc injector design initially developed by Lucas Aerospace. By the early-’90s, his business had expanded into injector sales and service for American cars and one of the first Corvette engines to become popular for RC Engineering, upgraded disc injectors was the LT5, the 5.7-liter DOHC V8 in the 1990 – 1995 Corvette ZR-1s.

In 1997, This reviewer installed a set of RC injectors in a 1995 LT5 and those same 16 injectors are still in service 18 years later. Every so often, I’ve pulled them out for inspection and testing and they pass with flying colors. Since then, in 2006, I installed RC Engineering disc injectors in my 2004 Corvette Z06 and, in 2012, in the modified 3.8-liter V6 in my ’01 Camaro. In both cases, driveability, especially throttle response, improved because of the disc injectors superiority over stock GM injectors.

Sadly, in 2014 Russ Collins died, but his RC Fuel Injection legacy continues. The Collins family still operates the business with John Welfringer as Manager. Today, RC remains a top electronic injector sales, service and consultation source in the performance aftermarket with Worldwide sales and the most sophisticated testing equipment in the injector service business.

Recently, I was changing the calibration of an LS7 in a 2012 Corvette Z06 and, in data logging with HPTuners VCM Scanner, looking at fuel trim values, I noted the right bank of cylinders was running more rich than was the left. Sometimes this just happens as a function of the way air flows into the intake manifold or because of slight cylinder-to-cylinder differences in distribution but then, sometimes it’s because the injectors are not close enough in injector-to-injector flow rates.

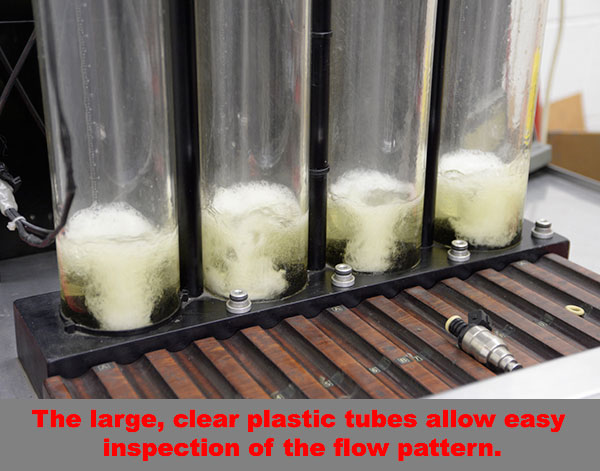

Wanting to cover all bases, I decided to pull the injectors for testing. On my next trip into the greater L.A. area one Thursday morning, I stopped off at RC Fuel Injection and had them flow tested. Injector Technicians Wayne and Keoki San Miguel (yep, they’re brothers) quickly tested my injectors in RC Fuel Injection’s “Certa-Flow 2000” injector flow test machine. Sure enough the “system balance” was 4.8 which means the highest (419 cc/min at 4 bar fuel pressure) and lowest (411.4 cc/min) flowing injectors differed by 4.8%. Ideally, system balance should be 1 to 1.5. A near 5% difference may not make a noticeable difference with a stock engine. but with one where you’re calibrating for exactly .86-lambda at wide-open-throttle, you’re going to see that difference, especially in a case like mine where my Innovate Motorsports wideband O2 sensor is only on one bank on cylinders. In that case, you want to make sure that the other bank of cylinders is not more lean than the bank your calibrating.

Wanting to cover all bases, I decided to pull the injectors for testing. On my next trip into the greater L.A. area one Thursday morning, I stopped off at RC Fuel Injection and had them flow tested. Injector Technicians Wayne and Keoki San Miguel (yep, they’re brothers) quickly tested my injectors in RC Fuel Injection’s “Certa-Flow 2000” injector flow test machine. Sure enough the “system balance” was 4.8 which means the highest (419 cc/min at 4 bar fuel pressure) and lowest (411.4 cc/min) flowing injectors differed by 4.8%. Ideally, system balance should be 1 to 1.5. A near 5% difference may not make a noticeable difference with a stock engine. but with one where you’re calibrating for exactly .86-lambda at wide-open-throttle, you’re going to see that difference, especially in a case like mine where my Innovate Motorsports wideband O2 sensor is only on one bank on cylinders. In that case, you want to make sure that the other bank of cylinders is not more lean than the bank your calibrating.

After looking at the flow test data, John Welfringer suggested that I leave the injectors with his guys for a five-hour session in one of RC’s ultra-sonic cleaning machines. Since I was headed back to my shop in Goleta, 150 miles away, he said they’d UPS the injectors to me that evening and I’d have them the next day.

Sure enough, Friday evening, UPS dropped of a box from RC Fuel Injection…love the quick turnaround on testing! Inside were my injectors and a test data print out saying that, once the injectors were cleaned, the system balance (421 cc/min, high, and 416 cc/min, low) was a far better at 1.2. What an improvement! During a road test with HPTuners Data Scanner recording engine controls data the long term fuel trim values were now closer together. It’s a safe assumption that, at wide open throttle, the bank-to-bank A/F was now closer, too.

Sure enough, Friday evening, UPS dropped of a box from RC Fuel Injection…love the quick turnaround on testing! Inside were my injectors and a test data print out saying that, once the injectors were cleaned, the system balance (421 cc/min, high, and 416 cc/min, low) was a far better at 1.2. What an improvement! During a road test with HPTuners Data Scanner recording engine controls data the long term fuel trim values were now closer together. It’s a safe assumption that, at wide open throttle, the bank-to-bank A/F was now closer, too.

So…why not an injector change to RC’s disc injectors? One reason is my engine is not yet modified to the point it needs a higher flowing injector. Scondly, the advantage of disc injectors is not as great as it once was because the Bosch pintle injectors used in the LS7 have much smaller pintles and, thus, can react quicker to changes in pulse width. Third and most important, there currently are no disc injectors available in the small package size used by GM on LS7s.

Want more information? Visit RC Fuel Injection’s web site which has a wealth of electronic fuel injector and electric fuel pump information.