C6, Naked and Exposed: Corvette Action Center's First Look at the 2005 Corvette - The Sequel: Finally, We Drive It! - Page 5 of 12

|

|

C6 Naked and Exposed - The Sequel: Finally...We Drive It!!! - Page 5 of 12

And, Talk to Some of the People who Built It

by Hib Halverson

Imagery by GM Communications, Richard Prince, U.S. Air Force and Sharkcom

©2005 Shark Communications

No use without permission

A Small-Block That Talks Like a Big-Block

Way back in the Muscle Car Era, the only engines in Vettes (or any other car for that matter) to make 400 pound/feet of torque were "big-blocks." Of course, Big-Blocks, at least the 396, 427 or 454 cu. in. iron-block behemoths we keep telling our kids about, haven't been in a Chevrolet passenger car in 30 years but, with the new, LS2 six-liter (366 cu. in.) V8, GM once again has a production engine which makes 400 horsepower and 400 lb/ft. torque.

Actually, LS2 is the same displacement as one of the old Big-Blocks, the little-known, "tall-deck", 366, used from 1966 to 1998 in medium-duty trucks, so...is this LS2 thing the Small-Block, which General Motors Powertrain (GMPT) calls it; or is it a Big-Block?

You pick.

Officially, the LS2 is the six-liter, all-aluminum, member of GMPT's Generation 4, Small-Block V8 Engine Family. Right now, there are two members of that group, the LS2 in the '05 Corvette and SSR and the 5.3-liter, LH6 in the Chevy TrailBlazer EXT and other GM, mid-sized utilities. In the wings is a Gen 4 for full-size trucks (probably in the 4.8, 5.3 and 6.0 sizes) along with the soon-to-be-iconic, "LS7", which will be the 2006 Z06's engine and, according to the latest Corvette Action Center intelligence, will be a 24-valve, 480-500hp milestone which, no doubt, will be the subject of intense discussion in about a year's time and for many years to come.

Right now, LS2 is the talking point and, once I got in a 2005 Corvette the first time, it wasn't long before I remarked (it was on that I-96 onramp driving with Tom Peters), "Whoa...this baby has some low-end grunt!"-and that's coming from someone who owns a Big-Block car.

Later, I had another telling, torque experience, this time with Dave Hill in the car, where I showed my polished driving skills by inadvertently starting out in second gear at a stop sign. Because of the LS2's better grunt and quicker throttle response off-idle; I almost didn't notice the error.

Interestingly, to some drivers who don't clearly understand what they feel (or not feel as the case may be); the LS2-powered C6 may not be perceived as the rocket ship it really is. Jordan Lee, a GMPT Staff Engineer who worked on the LS2 program and who rode with me on the second segment of the June 4th, media ride talked about that.

"At the bottom end," Lee told the CAC, "the LS2 is so much fatter than the LS6. There is one thing you gotta be cognizant of: a lot of people think, when they drive very high-performance sport cars, they're tuned only for high rpm. People perceive that because the bottom end is so weak. You step in the throttle at low rpm and the engine's flat, but then, all of a sudden, it feels like it's coming on the cam."

"The LS2 has a fat, broad torque curve so it's very satisfying down low, but you never have that rapid, flip-the-switch type of feel at higher engine speed. For my taste, and I think the majority of sports car drivers agree, it's more satisfying to have all that responsiveness and still have all the top end."

I'm with Jordan Lee on the "satisfying" thing (and the C6's acceleration numbers are with him, too), but I'm not so sure all Corvetters will agree with us because the erroneous belief that "comin' on the cam" is demonstrative of a powerful engine is so pervasive amongst urban legends in the car hobby. Reality is: if a normally-aspirated engine really has that on-off or on-the-cam feeling, it's either a race engine or a production engine with poor air flow management, either of which kind of suck on the street.

Conversely, the LS2's bulked-up, low-end adds to its LS6ish top-end to make a torque curve that's flatter than freakin' Kansas. Its lack of peakiness makes the car easier and more fun to drive. It idles nicer than an LS6 and has a tiny edge in throttle response. All this comes under the heading of "refinement."

A car hobby proverb, "Horsepower's for bragging. Torque wins races" explains why LS2, with five less horsepower, in a C6 Z51, which weighs about 225 pounds more than an '04 Z06 and lacks the Z06's wider rear tires, can run almost the same quarter mile time. While the LS2 and the LS6 have virtually the same torque curve above 3500-4000 rpm, below that, the LS2 wins the torque contest.

During our day with an early-production C6, we were not allowed to conduct any acceleration tests nor were we able to run the car for top speed. That will have to wait until we obtain a production C6 for a full-road test, however, we did get a lot of time to subjectively evaluate LS2 in a street driving environment and, as I've already said, this engine is a small-block that thinks it's a big block.

The test numbers we have were supplied by General Motors and, at this point, we are unable to verify them. That said, the numbers came from validation testing GM did prior to production of an advertising campaign. In today's litigious society, cases of manufacturers "padding" engine and/or vehicle performance data are becoming more rare because of the bad publicity and law suits. Ford's 1999 experience after its underperforming engines in Mustang SVT Cobras a few years ago is an example. We think GM's numbers are probably pretty typical of what a C6 Targa with Z51 will do in good air, on the right surface and in the hands of a good driver. According to GM, sixty miles per hour comes in 4.2-sec. The car does the quarter in 12.6-sec. at 115 mph. It's top speed is 186-mph. Sources who were present at the test session told us that if one folds back the sideview mirrors and tapes over the directional signals, a 2005 Targa will go 190-mph.

All this from a car that idles smoothly, can be driven around town by your grandma, meets emissions regulations in all 50 states and is, currently, the only 400-hp sports car which doesn't cost its owner a gas guzzler tax hit.

Not bad, I'd say.

LS2: The Techie Stuff

How did GMPT do it?

Well, first is 20 more cubic inches, from 346 to 366, but that doesn't fully explain why there is so much more torque. The reason the LS2 talks softly but carries a big stick is Powertrain's quasi-religious devotion to air flow. Significant improvement was made in reducing restriction in the intake tract. Restriction was also decreased in the exhaust manifolds, the catalytic converters and the exhaust system.

How valuable is flow? LS2's torque output is proportionately larger than its displacement increase. It also makes virtually the same power as the 405hp LS6 using a camshaft having a profile which has less lift and duration. Repeat after me: "Flow is good."

As Jordan Lee and I drove around rural Michigan, we got more into the program which resulted in the LS2. I wondered what the Gen 4 Team's mission was.

Jordan Lee: With the Gen 4, and the new generation, C6 Corvette, they (Dave Hill's "Team Corvette") had some pretty stringent requirements. They wanted a base car that was (quicker and) faster, had more torque, more throttle response and they wanted this with no detriment to fuel economy.

Dave Hill's group gave us the requirements-"Here's what we want your engine to do."-then they asked, "What can you provide?" We took their needs and developed our engine-specific requirement.

The mission of the Gen 4 Small-Block Product Team was to deliver the extra performance that the C6 Corvette required and the better fuel economy that the mid-sized, sports-utilities wanted while improving quality and refinement at the same time."

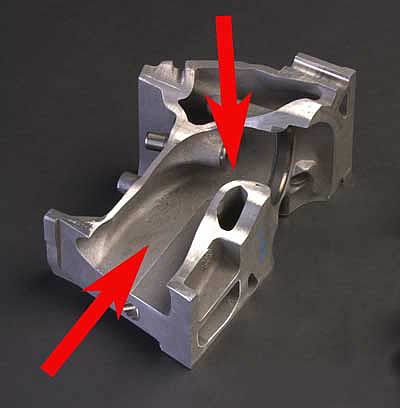

Image: GM Communications

CAC: Let's take a look at the places you reduced restriction, the intake and exhaust sides. The intake manifold-it is quite a bit different, I take it.

JL: Yeah. The construction technique (vibration welding) is different. The runner geometry has been optimized for a six-liter displacement.

CAC: A little bit more plenum volume?

JL: Mostly runner shape-a little bit larger bell-mouth. Not significant. Not a huge amount, but a little bit different.

CAC: Was vibration welding developed by GM or by the supplier?

JL: It's now a more common technique for intake manifold construction than "lost core," used for the first wave of composite-plastic manifolds. It's a very complex process and requires a lot of money for capital equipment.

Vibration welding has been in the industry for quite some time for other types of components, like canisters and reservoirs. The pieces are molded separately in more simple injection molding tooling and then the pieces are assembled, held in position and vibrated until the interface melts.

CAC: Melts? As a result of heat generated by the localized friction of the two parts moving against each other?

JL: Yes.

CAC: The manifold material is still that Nylon 66?

JL: No. It's a glass-filled, Nylon 6. Nylon 66 is the material commonly used in lost core. Nylon 6 is commonly used for vibration welding-little different additives in the polymer that makes it more amenable to welding.

CAC: Fuel rail?

JL: Fuel rail is new. It's stainless steel and it's been reconfigured in a few areas in order to accommodate the new manifold. No real significant differences.

CAC: Injector flow capacity?

JL: Went up from 3.6 grams per second to 4.1 g/sec. (32.5 lb/hr.) at 400 KPa.

CAC: Is the targeting of the injectors any different?

JL: No. It's the same. We have very strict guidelines for injector targeting-the back of the valve-and we've strived to do that in every application for many, many years, now.

It does have a larger throttle body with a 90-mm. bore, as opposed to the earlier one on the Gen 3, which was 76-mm.

The vehicle (platform engineering team) has, also, redesigned their induction system for lower restriction. It's actually 31% lower restriction than that used with the LS1.

CAC: This would be the air box and the air duct?

JL: And the air meter.

CAC: The air meter: carry over or new part?

JL: Carry over.

CAC: From LS6 or LS1?

JL: The LS6 was actually identical to the LS1, except for a flow straightener-like a little honey-cell-which was removed on the LS6.

CAC: Does the LS2 have that?

JL: Yes.

CAC: Why'd you put the flow straightener back in?

JL: For emissions controls, we rely on very accurate metering of the air. In order for the air meter to do it's job well, as the air passes through it; flow has to be very laminar, no matter what the induction system it's bolted to, no matter what throttle position you happen to be at.

When we take that straightener out, we get more variation of the air flow signals. On the LS6, that was deemed acceptable from an emissions and a controls perspective, but with the LS2, we wanted to put it back in so we could maintain better control. The improvements we had in the other inlet system components was an enabler to put the screen back in.

CAC: You need the improvement in emissions controls with the screen but with other decreases in restriction, there's a net gain.

JL: Correct. The thing to keep in mind is that the straightener allows the air meter to be much more accurate.

Once you you get past the intake manifold, the cylinder heads and the camshaft affect air flow. LS2 heads are the same as those on an '01 (375hp) LS6. Note that they use the shorter, solid-stem valves rather than '02-'04 (405hp) LS6's exotic, longer, hollow-stem intake valve and sodium-potassium("NaK")-filled, hollow-stem exhaust valve. Because the LS2 camshaft is less aggressive, lighter valves are unnecessary to keep the valve train stable all the way to LS2's 6600-rpm rev limiter. The rest of the LS2 valve gear is also the same as '01 LS6.

The cam in the LS2 is similar to the '01 LS6 cam. It uses the same profile but the part number is new because the cam position sensor target was moved from the cam to the camshaft sprocket. Valve lift is .525-in. and duration at .050-in lift is 204o int/211o exh.

On the exhaust side, Powertrain's engineers made additional improvements, first, with the exhaust manifolds themselves. They are made of a new material, cast iron with a higher silicon and molybdenum content. The additional strength and durability of this new material allows nominal wall thickness to be reduced from 4 to 3-mm and that made for a 10.6 lb weight reduction. Additionally, these manifolds are designed for use with close-coupled catalytic convertors, which bolt right to the manifold outlet and enable cat "light-off" in a shorter time after startup. Today, the majority of an engine's exhaust emissions come between startup and cat light-off, so the close-coupled cats are a significant improvement-to the point that all base C6es loose their pup cats, the auxiliary converters used on California cars in 2000, in 2001 on all Corvettes and from 2002 to 2004 on LS1s. Going pupless also reduces restriction and weight. LS2 cats are similar in design to those introduced in 2002 on the LS6.

The exhaust system has some changes for less restriction, too, mainly that the transverse mufflers and their four, 90-deg. tube bends were scrapped. The storage well in the back of a '97-'04, left over from the early design stages when C5 had a spare tire, is gone. That volume of space is now used to house two longitudinally-mounted mufflers which have less restriction though larger internal volume and various acoustic enhancements. In total, the reduction in exhaust back pressure is about 10% over the old 2001-up base system.

So, we've got a 31% reduction in restriction in the intake system, a 10% reduction in exhaust restriction and the LS6 cylinder head. Now that, dear reader, makes for some air flow. Add to that 20 cubic inches and a little bump in compression and you get a 400 horsepower, six-liter motor.

|

|