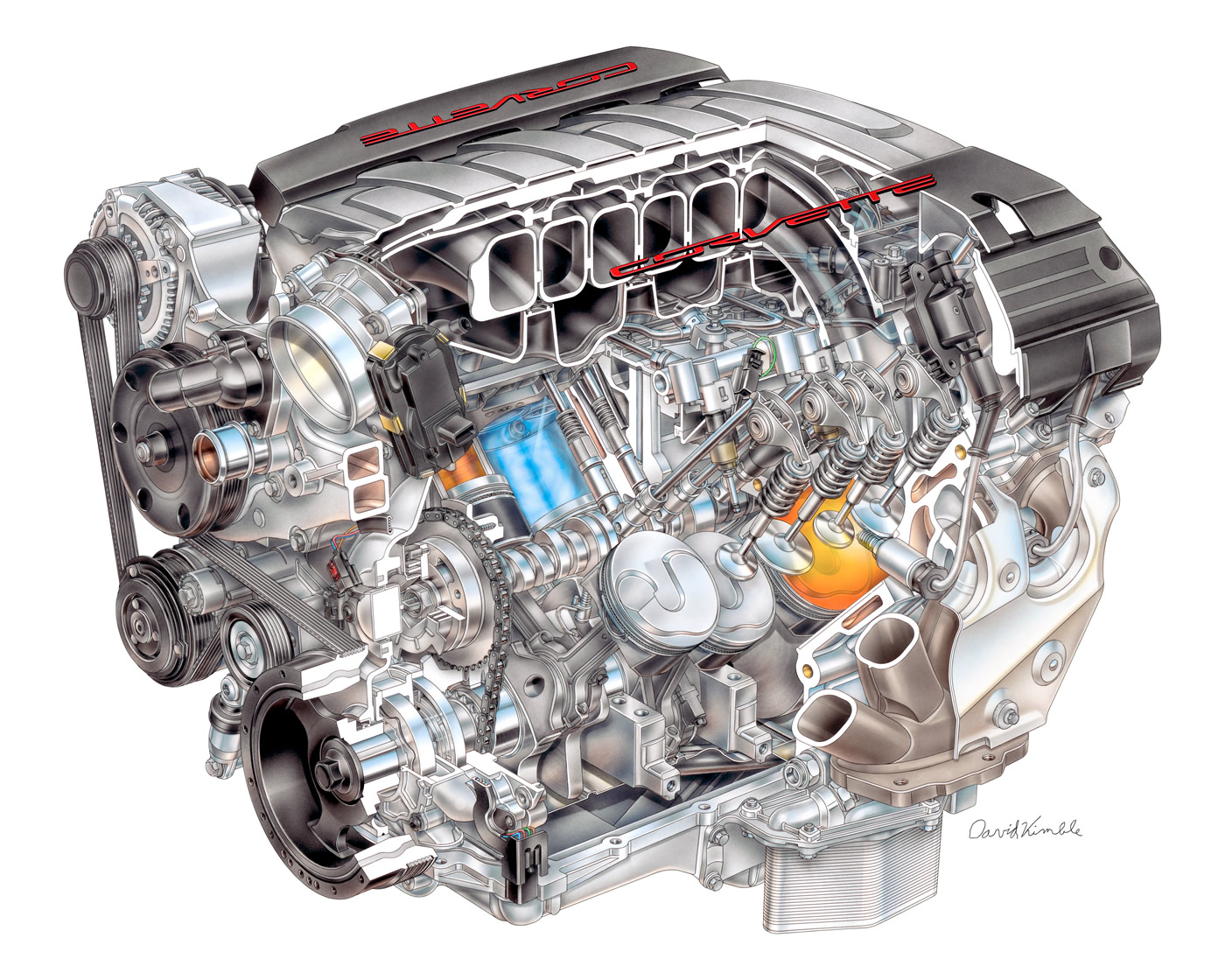

2014 C7 Corvette LT1 Fact Sheet #2 - Gen 5 Small Block Lubrication System

Source: GM Media

The new Gen 5 Small Block's lubrication system supports Next-Gen advanced technologies, including Corvette's first applications of direct injection, Active Fuel Management and continuously variable valve timing. They help the completely reengineered 6.2L engine produce the greatest standard horsepower, torque and efficiency in the car's 60-year history.

Highlights include:

- Standard wet-sump lubrication or available high-performance dry-sump system

- All-new variable-displacement, dual-pressure-control oil pump with increased flow capacity for optimal oiling efficiency

- Pressure-activated oil-spray piston cooling for greater efficiency, durability and quietness

- New windage tray design enhances oil flow control and crankcase breathing

- Rocker covers with patent-pending positive crankcase ventilation system for greater oil life and lower oil consumption

- Dexos semi-synthetic motor oil, including a 5W30 specification for the Corvette, that helps reduce friction to enhance the engine's efficiency.

The available dry-sump oiling system promotes exceptional lubrication system performance during extended high-rpm use under high cornering loads. It includes two stages of oil pumping, including the new, dual-pressure-control and variable-displacement vane pump and a scavenge pump.

Efficient oiling

Variable displacement enables the Gen 5's oil pump to efficiently deliver oil as demanded by the engine's operating conditions. Its dual-pressure control enables operation at a very efficient oil pressure at lower rpm coordinated with the Active Fuel Management and operation at a higher pressure at higher engine speeds providing a more robust lube system with aggressive engine operation. As with Gen 3 and Gen 4 Small Block engines, the new vane-type oil pump is crankshaft-driven.

Oil-spray piston cooling, in which eight oil-spraying jets in the engine block drench the underside of each piston and the surrounding cylinder wall with an extra layer of cooling, friction-reducing oil, is standard on all Gen 5 engines – previously it was only a feature of the supercharged LS9 and LSA engines. The oil spray reduces piston temperature, promoting extreme output and long term durability. The extra layer of oil on the cylinder walls and wrist pins also dampens noise, for a quieter driving experience.

For optimal efficiency, the oil jets are used only when they're needed the most: At start-up, giving the cylinders extra lubrication that enhances the engine's durability, and at higher engine speeds, when the engine load demands it.

A redesigned windage tray is also used with the Gen 5, featuring a new oil scraper design. It enhances performance and efficiency by improving oil flow control and bay-to-bay crankcase breathing. The tray is mounted on the bottom of the engine, between the main bearing caps and oil pan.

Dry sump details

The dry sump system scavenges liquid oil and any resulting mixture of oil, air and crankcase gases from the bottom of the engine oil pan through an internal scavenge return tube. This oil mixture is pumped to the top of the dry sump tank (mounted in the engine compartment but external to the engine). Within the tank, the oil mixture is tangentially spilled out on a spiral-shaped internal baffle where the contact and flow about the internal surfaces of the tank promote separation of air and gasses that are entrained in the oil. These gasses are directed by the PCV system (see section below) through a series of baffles and tubes back to the combustion chamber to be burned.

The de-aerated oil is directed down the walls of the tank to collect in the 10.5-quart reservoir (wet-sump application feature a six-quart capacity), conditioned and ready for use. The second stage of the dual-stage gerotor pump then draws the conditioned oil from the tank and pressurizes it, feeding it to the engine via the oil filter and oil cooler. The routing of the engine oil to and from the dry sump reservoir also provides the benefit of passive oil cooling.

PCV-integrated rocker covers

One of the most distinctive features of the all-new Gen 5 engine is its domed rocker covers, which house a patent-pending integrated positive crankcase ventilation (PCV) system that enhances oil economy and oil life, while reducing oil consumption. It also contributes to low emissions for the Gen 5.

The rocker covers also hold the direct-mount ignition coils for the coil-near-plug ignition system. Between the individual coil packs, the domed sections of the covers contain baffles that separate oil and air from the crankcase gases – about three times the oil/air separation capability of previous engines. Each cover features and inlet and outlet path for the crankcase gases, with the separated oil dropping back onto the engine within the covers and the remaining air/gases circulated back into air intake stream for combustion. The system also prevents moisture from accumulating in the engine.

This integrated PCV system is an essential contributor of the Gen 5's efficient performance and long-term durability – and the domes for it on the rocker covers make the Gen 5 engine instantly recognizable.

# # #

|