A Dose of Digital: Part 1 - The Basics - Page 5 of 5

© 2010 by Hib Halverson

No use without permission, All Rights Reserved

![]() Discuss this article

Discuss this article

So Now...How do you Fix it?

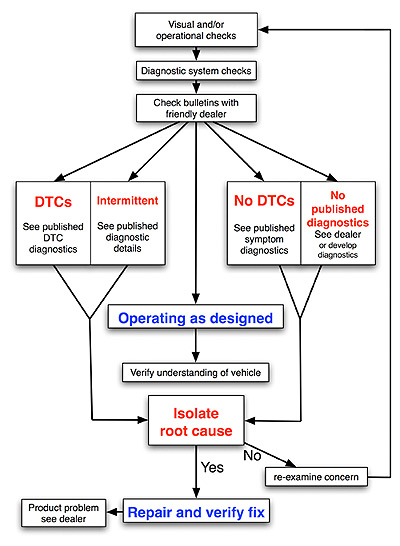

A good way to tackle engine controls problems is with a modified version of GM's "Strategy Based Diagnostics". If your first instinct is, "Forget all that strategizing and let's start replacing parts." for you, we have Rule Number One: Unless you have advanced skills and a lot of experience, don't ignore factory service data. After 25 years working on these systems, the FSM is still our "bible".

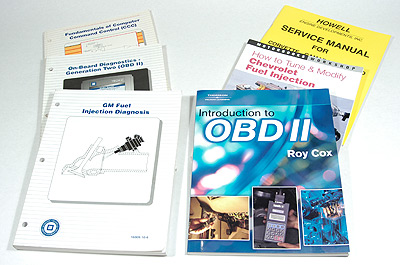

Rule 2: Know how engine controls work. Diagnosis will more difficult if you don't understand system function. FSMs contain some discussion of this along with invaluable wiring diagrams. Some books, listed in a sidebar, also, contain system explanations.

Rule 3: Be mindful of the differences between current and history codes. If the code is current, the problem exists in real time. If you have a history code, there are two possibilities: 1) the problem has either occurred and gone away or is random or intermittent, destined to occur again. 2) the affected system is still faulty but may not be active and, not being active, its OBD are disabled. In that case, activate the system and see if the code turns current.

Rule 4: Many use "Intermittent" to describe two different anomalies. There are "random" problems, which occur occasionally with no specific criteria, and there are "intermittent" problems, for which diagnosis has yet to occur, but happen repeatedly with specific criteria. Randoms and intermittents can be challenging.

Rule 5: Many engine controls problems are caused by faulty wires and poor connections rather than modules, sensors or actuators. Keep that in mind during visual and operation checks, especially if the problem is random or intermittent. This is not to say that modules, sensors and actuators never have problems, but it is to say that the first place you need to look is wires and connections.

Sidebar

Got Manuals?

Bet you know at least one DIY who won't read service manuals. They're the folks who take forever to do a job, always know more than the "f---ing factory", believe GM service data is a poor value, but never say how much money they waste on parts they don't need. The automotive DIY community so doesn't need these guys.

Full Story: Got Manuals?

Rule 6: If an OBD-I MIL is on, record the codes then clear them and road test the car. If your tester or scan test software logs data; during the road test, have it set to trigger when the code sets. During the road test, if the light stays off, the problem is random or intermittent. If the light comes on again, you've got a hard code and your snapshot data will help during the solution.

Rule 7: I you're getting an OBD-II MIL, using a scan tester or scan test software, read the codes and note their failure records. Contrary to Rule 6, in most cases, with OBD-II, it is not advisable to clear codes until repairs are complete.

Rule 8: Don't out-trick yourself. Yeah, all this stuff is high-tech and DIY techs must know more and have more expensive tools but, don't let big clues get by you. For example: faults like faulty ground connections, a marginal battery or a failing alternator can cause all kinds of engine controls symptoms, yet many forget to check those items, first.

Rule 9: Don't forget: there are still mechanical systems hiding under all that electronics. Compression problems, cooling system trouble, exhaust restriction or leaks, worn engine parts and other anomalies can cause codes. Say you're getting code P0300, which some call "random misfire". A wide variety of problems, both electronic and mechanical, can cause that. Some may seem way out there but can trick OBD-II in to setting a misfire code. For example, vibration caused by brake rotor thickness variation or an out-of-balance drive shaft can cause DTC P0300.

Rule 10: Don't underestimate engine controls' ability to supply accurate diagnostic information, but, also, remember that data obtained from on-board diagnostics are sometimes clues rather than solutions. Example: recently, we had an OBD-II engine which was randomly setting DTC P0174 (lean exhaust from the left bank of cylinders). Road testing with the Mastertech demonstrated short and long term fuel trim values typical of a vacuum leak, ie: way high numbers at idle and low-speed/light load but more nominal fuel trims as engine speed and load increased. Problem was: at first, we couldn't hear the leak. After checking easy stuff, vacuum hoses, easily-accessible gaskets and seals, we moved to throttle body gasket, EGR pipe seals and injector seals, but still didn't find the problem. As a restricted fuel system causes similar, but not exactly the same, symptoms; we started down that route (thinking we knew more than the system was telling us) and fully-tested the fuel system, replaced the fuel filter and flowed the injectors-all a waste of time. Finally, the leak got bad enough for us to just barely hear it coming from the left front of the engine. Spraying the parting line between the manifold and head with some contact cleaner and the Mastertech showed the short-term fuel trim momentarily going way lean as the contact cleaner was ingested in but, as soon as the spray stopped; the STFT skewed back, rich.

Intake gasket you think?

Actually, not.

I changed the intake gaskets and the problem persisted, but I could still hear a hiss and I could spray some contact cleaner along the top of the manifold/head parting line at the front of the engine and notice the fuel trim momentarily normalizing.

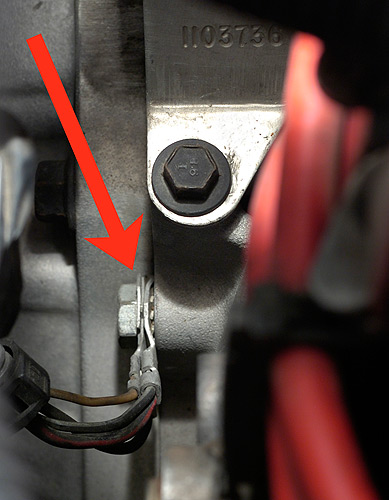

I obtained a mechanic's stethoscope-the unit sold by Lisle (PN 52750) is a good one-and with that, I traced the hiss to a crack in the metal tube that runs from the digital EGR valve up to the intake manifold. The valve itself is located just in front of the left cylinder head. The contact cleaner spray was vaporizing on the hot head then flowing along the top of the head, down the front of the head then was ingested at this crack in the EGR pipe half an inch away from the front of the head. A new EGR pipe and the problem was solved-but a lesson was learned.

In the next couple of installments of this series, we'll take a look at some diagnostic tools.

Sidebar

Orphaned, Bastardized but Certainly Historic

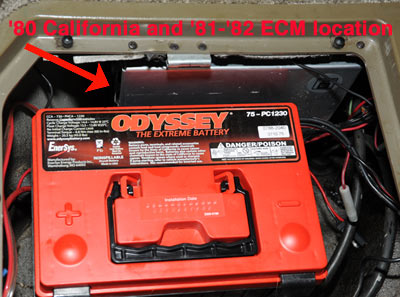

The Strange Case of the '80 California Cars

Set the Wayback Machine for late-1970s. For the coming 1980 model year, Chevrolet was facing exhaust emissions regulations more stringent in California than in other states and those new standards were going national in '81. These laws drove a major effort at Chevy Engineering to perfect digital electronic engine controls as a way to maintain drivability while meeting those requirements.

Full Story: Orphaned, Bastardized but Certainly Historic

Sources

Bosch Diagnostics

2030 Alameda Padre Serra

Santa Barbara CA 93103-1716

800.321.4889

www.boschdiagnostics.com

CarTech

39966 Grand Av.

North Branch MN 55056

800.551.4754

www.cartechbooks.com

Delmar (Chilton manuals for pros)

5 Maxwell Drive

Clifton Park NY 12065-2919

800-648-7450

www.delmarlearning.com

EASE Diagnostics

187 Commerce Dr.

Scott Township PA 18447

888.366.3273

www.obd2.com

Haynes Manuals, Inc.

861 Lawrence Drive

Newbury Park, CA 91320

800.442.9637

www.haynes.com

Lisle Corporation

807 E. Main Street

P.O. Box 89

Clarinda IA 51632

712.542.5101

www.lislecorp.com

Motorbooks International

PO Box 1

Osceola, WI 54020

800-826-6600

www.motorbooks.com

Z-Industries

31200 Santiago Rd.

Temecula CA 92592

951.303.6857

www.z-industries.com/

Zip Products

8067 Fast Lane

Mechanicsville VA 23111

800.962.9632

www.zip-products.com