Ruthless Pursuit of Power: The Mystique of the C6 Corvette LS7 Engine - Page 18 of 26

Ruthless Pursuit of Power: Lucky Seven Edition: The Mystique of the 7-Liter, 7000-RPM, LS7 - Page 18 of 26

|

|

by Hib Halverson

© May 2013— Updated: February 2016

No use without permission, All Rights Reserved

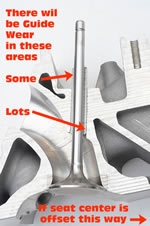

The Bigger Oops: LS7 Valve Guide Wear

The second and more serious LS7 affliction has been premature valve guide wear. This problem has been the subject of over 7000 posts to various threads in the Corvette Forum's C6 Z06 board, alone, going back to the late '00s and that's just counting posts in threads with over 500 replies. The Corvette Action Center and other Corvette- and LS-engine-related forum sites, also, have LS7 guide wear content.

By 2011, even discounting some of this content as rants by GM-haters, trolls, lawyers looking for plaintiffs and uninformed whiners, it was clear that an inordinate amount of C6 Z06 owners had engines with prematurely worn valve guides. Some of those Corvette customers believed their worn guides occurred because the LS7 cylinder head and/or valvetrain designs were flawed. Further, some of those customers were infuriated by what they saw as GM's lack of appropriate and timely response to their concerns. Based on the many angry guide-wear-related rants we read which included statements such as: "I'll never buy another GM product again!" it's likely that GM has lost sales over the LS7 guide wear debacle.

Not only has this problem been a cause of aggravation and alarm in the Corvette community for the last several years, it has caused hand-wringing inside GM. By early 2012 it was clear from anecdotal accounts posted to Internet forums that, while GM had yet to publicly acknowledge a problem with LS7s, it had been doing warranty replacements of heads and even compete engines due to premature valve guide wear. As of this writing, in January 2016, GM's hand wringing about LS7 valve guide wear and warranty replacements of heads and engines due to that problem is ongoing.

This situation became more complicated with the filing of a class action lawsuit against GM over LS7 heads with worn guides. The suit, Pilgrim et al. v. General Motors LLC, was filed in U.S. District Court for the Central District of California on 14 October 2015 by 45 C6 Z06 owners. At this writing, in late January 2016, both the plaintiffs and the defendant had stipulated that the Court will stay the case until at least 17 February 2017, pending a decision by the United States Bankruptcy Court for the Southern District of New York which is adjudicating cases dealing with the bankruptcy of the "Motors Liquidation Company" aka "The Old GM". In short, this case is going to drag on for years.

In late-2012, during research into guide wear for the original version of this article and a second, more comprehensive, six-month study of the situation in mid-2014 for the first revision of this story, the Corvette Action Center contacted General Motors and had a number of telephone and email exchanges with Tom Read, GM Powertrain's Communications Manager. Eventually, In late March of '15, GM invited the Corvette Action Center to GM Powertrain Headquarters in Pontiac Michigan for a meeting with the team of GM Engineers currently working on the LS7 engine. This visit included a visit to the GMPT "Inspection Department" deep within the bowels of Powertrain Headquarters to witness GMPT's use of a coordinate measuring machine (CCM) to measure valve guide wear. Our visit to GM Powertrain and additional research the CAC undertook prompted the second, and most current, revision to this article.

Besides GM, in researching the LS7 guide wear issue, the CAC contacted six other sources familiar with LS7 engines. One of the extra-GM sources is a supplier which was involved with the LS7 program. Another is a Corvette performance enhancement business which often works with LS7s. Two of them are well-known cylinder head specialty businesses which service and modify street high-performance and racing Gen 3/4 V8 cylinder heads. The last two are engineering firms known for performance development of LS7s and other GM engines.

Can You Say "Con-cen-tri-ci-ty"?

One of the engineering firms we interviewed for this article was Katech, Inc. of Clinton Township, Michigan, northeast of Detroit. Since it was founded in 1977 by engine building greats Fritz Kayl and Warren Frieze, Katech has been an engineering and performance development firm specializing in Chevrolet engines. It had a long and successful association with General Motors as the engine supplier for Corvette Racing from 1998 to 2010 along with being involved with consulting and testing during the LS7 development in the first half of the '00s. Katech, also, has a thriving aftermarket business with LS7s, supplying street high-performance and racing engines to worldwide customer base. Since the LS7 was introduced in 2006, Katech has seen a lot of LS7 cylinder heads come though its doors and has amassed a significant body of evidence supporting the contention that the most common root cause of excessive valve guide wear in the LS7 cylinder head is lack of concentricity of the valve guide and valve seat centerlines.

This lack of concentricity, also known as "valve seat run-out", is caused by inaccurate machining of the cylinder heads. The GM supplier responsible for machining and assembling LS7 heads was Linamar Corporation of Guelph, Ontario, Canada.

The other performance engineering firm along with the LS7 parts manufacturer we contacted, on condition of anonymity, echoed Katech's findings, i.e.: that the guide wear problem is caused by inaccurate machining of cylinder heads and that the nature of the inaccuracy is valve seat centerlines and valve guide centerlines which are not concentric.

Valve guides and seats which are not concentric may cause excessive side loading of the valve stems as they move in the guides. That side loading can cause high levels of guide wear and, eventually, valve seat wear, too. The greater the magnitude of non-concentricity, the quicker the wear occurs. Initially, an engine may have no outward symptoms of a problem, however, once valve guide wear becomes severe–significantly greater than GM's "Service" limit of .0037-in.–the engine may exhibit increased valve noise and high oil consumption. At some point, the engine begins to misfire due to poor intake valve sealing and the MIL will come on. If the engine is subjected to high rpm operation with severely worn guides, a catastrophic failure is likely.

The second engine development firm to which we spoke has measurements of LS7 guides and seats which demonstrate the non-concentricity problem. Unfortunately, it refused the CAC's several requests to examine the data, but then–we have our own measurements taken from the head we used for imagery in this article along with a set of low-mileage used LS7 heads removed from the CAC's 2012 Z06 and the heads supplied by GM as warranty replacements.

Our first checking head had never been run on an engine and has an end combustion chamber sliced off leaving five valve seats–three intakes and two exhausts–intact. We used a Goodson Valve Seat Runout Gauge (PN VSG-375) and a Goodson Solid Taper Pilot (PN P-5315N) to measure the runout of the five good seats. One was right at Production maximum of .002-in. Another was over the production limit, at 0025-in. Both those were intakes and their lack of concentricity could cause a higher rate of guide wear. The rest of the seats had acceptable runout. Our measurement of this sectioned head's seat runout was only the "tip of the iceberg" as you shall see later in this article.

The two head service facilities we interviewed, both of which are nationally known specialists in GM Gen 3/4 cylinder head maintenance, repair and modification, had split opinions on the causes of LS7 guide wear.

The first cylinder head service we contacted told us the problem is caused by guide and seat centerlines not being concentric. They added that one reason they concluded that is they only see frequent guide wear problems in heads machined by Linamar: those for the LS7. With heads from other engines, such as the LSA, the LS3 and various Gen 3/4 truck engines, premature valve guide wear is uncommon. They, also, noted that the cross-section of the wear in some of the bad guides in LS7 heads was oblong in shape. If non-concentric guide and seat centerlines were forcing the valve head sideways just as it contacted the seat, that would tend to cause significant guide wear in one direction and less wear in others.

|

|