Ruthless Pursuit of Power: The Mystique of the C6 Corvette LS7 Engine - Page 8 of 26

Ruthless Pursuit of Power: Lucky Seven Edition: The Mystique of the 7-Liter, 7000-RPM, LS7 - Page 8 of 26

|

|

by Hib Halverson

© May 2013— Updated: November 2014

No use without permission, All Rights Reserved

An LS7 piston pin, or "wrist pin"--arguably one of the most highly stressed parts in a high-performance engine--is made of a gas-nitrided, chromium-molybdenum-vanadium steel meeting the 31CrMoV9 specification. This is a more robust material than normally used in GM V8 pistons. it allowed the wall thickness of the pin to be less and the inside diameter to be tapered to reduce mass but still enabled the pin to meet GM's abusive fatigue life tests. The piston is phosphate-coated, the main purpose of which is to improve the reliability of the pin bores during the break-in period. The pin locks are circlips, but they're made with 1.8-mm rather than 1.6-mm wire to increase the circlip's tension. During development, according to then Small-Block Chief, Sam Winegarden, the LS7 engineers learned that, at high RPM, the loads on the 1.6-mm circlip at top-dead-center and bottom-dead-center can deform it and pop it right out of the pin lock groove. Going to the more robust circlip solved that problem.

Additional mass reduction comes in shortening the piston pin, but to do that and preserve the ability of the pin bosses to carry the load, the pin bores were moved closer together and the tops of the pin bores curve inward to further strengthen that area. To clear those parts of the pin bores, the small end of the connecting rod is formed with a pronounced taper with the top being more narrow. Another reason for a shorter pin? It provides clearance between the crankshaft reluctor wheel and number eight piston.

The piston top has four valve reliefs which, according to Aaron Dick, are not necessary with the stock LS7's valve lift. They exist because, after the design was finalized, GM wanted slightly less compression, so four valve reliefs were added. An unintended, but sometimes welcome consequence, is that these reliefs provide adequate valve-to-piston clearance for some aftermarket camshafts, such as Katech's "Torquer" series of LS7 cams, having more aggressive profiles without having to change pistons. The ring grooves are machined with a slight upward tilt which counteracts the rings' tendency to flex downward under operating pressures and temperatures. The top ring land is hard anodized to prevent microwelding on the flanks of the ring groove.

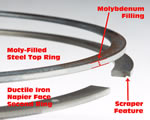

The LS7 ring package starts with a 1.2-mm, moly-filled, steel top ring. It is "coined" to give it an upward twist which flattens under combustion pressure improving ring seal. The second ring is, also, 1.2-mm, but is made of ductile-iron and has a Napier-face for enhanced oil control. The oil ring is a 2-mm, 3-piece unit consisting of two gas-nitrided rails and an expander.

Most of this cutting-edge piston technology is aimed at reducing mass but, also, increasing durability. Aaron Dick's closing statement says it all about the level of technical sophistication in the piston assembly: "it's a very, highly-engineered piece for a specialized application."

|

|